Service and maintenance tips on our new service page!

If you’re using a Tungsten grinder, you already know the importance of keeping it in top condition to get the most out of your investment. But did you know that proper service and maintenance can also help you extend the service life of your Tungsten grinder?

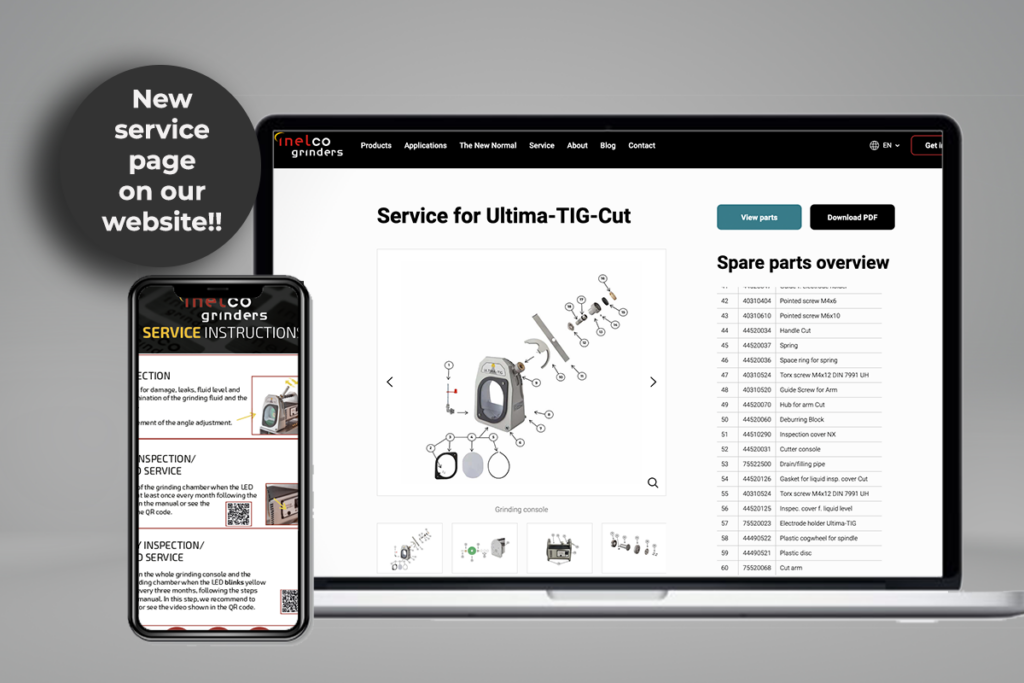

That’s why we’re excited to announce the launch of our new service page dedicated to service and maintenance for our Tungsten grinders. Our goal is to provide you with the comprehensive information you need to properly service and maintain your grinder, ensuring optimal performance and a longer service life.

On our service page, you’ll find detailed service instructions, as well as easy access to exploded-view drawings with a list of parts for each grinder model. And the best part? You can download these service instructions and PDF files with the exploded-view drawings alongside a list of the respective parts right from our website.

We’ve also added service videos to our service page, providing you with step-by-step instructions on how to service your Tungsten grinder. With these videos, you’ll be able to see exactly how to maintain your grinder, making it easier and more convenient than ever.

Find the information you need quickly

At Inelco Grinders ®, we understand that your time is valuable, which is why we’ve made it easy for you to find the information you need quickly and easily. By taking advantage of our service and maintenance resources, you’ll be able to keep your Tungsten grinder running smoothly for years to come. This does not only mean that you are getting the most out of your investment, but also by servicing your equipment you are taking part in a more sustainable agenda. By servicing your machines regularly and ensuring they have a longer service life it can contribute to sustainability in several ways, such as

- resource conservation,

- waste reduction,

- energy efficiency, and

- by servicing your machines in-house we can avoid the transportation when you send it for repair to our location, which can be costly on the environment.

Read another blog post explaining in detail how servicing your machine is a more sustainable move here(link).

So why wait? Head over to our service page now to access our comprehensive service and maintenance resources for your Tungsten grinder. And if you have any questions or need additional support, don’t hesitate to reach out to our team of experts.

We’re here to help you get the most out of your investment.

#TungstenGrinder #TIGwelding #ServiceAndMaintenance #LongerServiceLife #ExplodedViewDrawings #Parts #ServiceVideos #Productivity #Efficiency #Investment #CustomerSatisfaction