It’s common knowledge that TIG welding demands a sharpened Tungsten electrode, but understanding why is crucial. Let’s dive into some key tips to ensure your grinding process not only sharpens the electrode but also maintains high-quality welding.

1. Always Grind Your Tungsten Electrode:

Why sharpen the Tungsten? The primary reason is to facilitate the ignition of the arc. A ground tip significantly improves the arc’s ease of ignition compared to a 180° factory blunt tip, ensuring a smoother welding experience. So, make it a rule of thumb—always grind your Tungsten for optimal performance.

2. Choose the Right Geometry:

Grinding angle matters! Tailor your grinding angle to your application. A sharper point widens and stabilizes the arc but risks heat susceptibility, while a truncated tip offers deeper penetration and a more narrow arc but may be harder to ignite. Hence, find the geometry sweet spot for your welding needs. You can read more about when you should truncate the tip here.

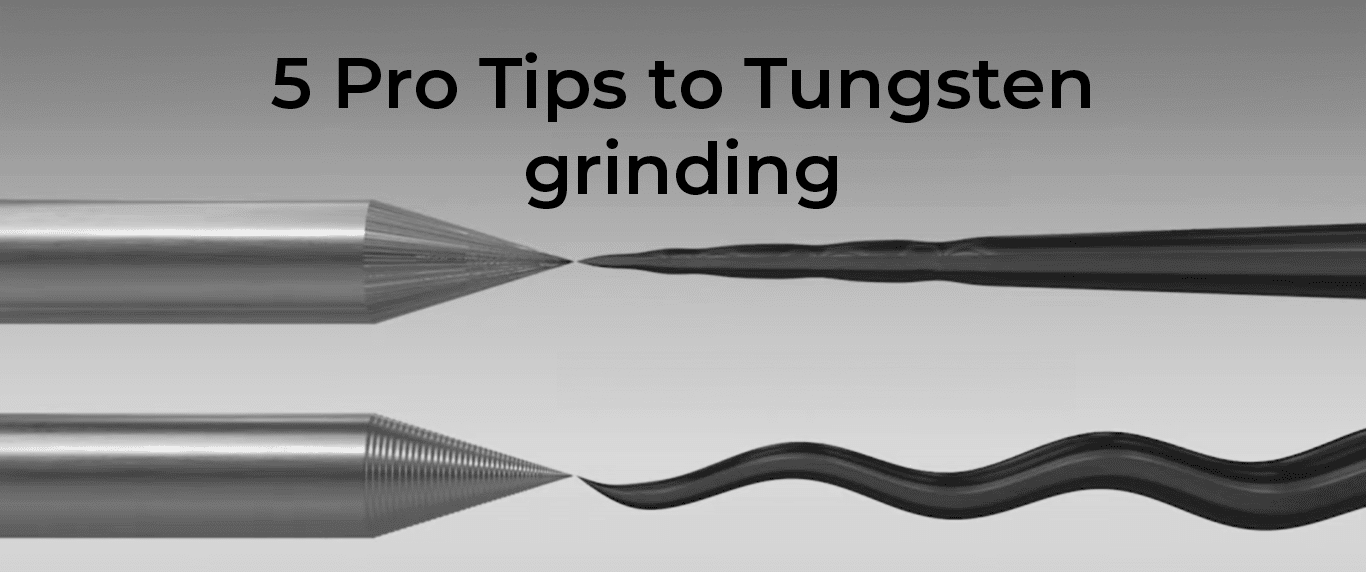

3. Grind Your Electrode in the Longitudinal Direction:

Precision matters! Opt for lengthwise grinding to ensure an arc ignites at the tip of the Tungsten. Crosswise grinding may result in unwanted ridges, leading to a wandering arc during welding. Keep it sleek and streamline your grinding process.

4. Select the Right Grinder:

Safety first! Avoid conventional grinders, as Tungsten dust, when combined with other metals, can be carcinogenic. Choose a Tungsten grinder to contain the dust and keep your workspace free from harmful particles. Safety meets efficiency with the right tool.

With the Ultima-TIG grinder you get unparalleled precision through its variable angle setting, as well as optimal control over your grinding process. Its innovative design includes an electrode holder that facilitates precise centering of the tip, enhancing overall accuracy. By incorporating wet grinding technology, this grinder effectively prevents electrode overheating, preserving the integrity of the Tungsten during the grinding process. Additionally, its high grinding speed ensures not only faster results but also a consistently smooth surface finish.

5. Don’t Break Your Tip After a Dip:

Stay sharp! When faced with a dipped Tungsten covered in cold steel, opt for a regrind rather than breaking it. When breaking the electrode, the outcome is often that the electrode will split lengthwise. Therefore, a step in the right direction is to cut the electrode, however; avoid using an angle grinder. It is crucial to cut the Tungsten electrode in a sealed chamber, so to prevent injuries and the dust to disperse. Here you can take a look at our solution; the Ultima-TIG-Cut.

Prioritize safety and precision to keep your Tungsten Electrode in top-notch condition.

In conclusion, grinding your Tungsten is more than just a routine—it’s a craft that demands precision, safety, and expertise. By incorporating these expert tips into your grinding process, you’re not just sharpening an electrode; you’re honing a key element for welding excellence. Improve the Tungsten grinding and watch your welding quality follow.