At Handwerkskammer Heilbronn-Franken, where craftsmanship meets education, a loyal commitment to occupational health and safety takes precedence. Discover how the institution’s adoption of Inelco Grinders ®‘ Ultima-TIG® not only ensures unmatched precision but also creates a learning environment that prioritizes the well-being of every individual, from trainees to seasoned professionals.

At Handwerkskammer Heilbronn-Franken offers an array of courses and seminars tailored for diverse professional stages, from apprentices to seasoned entrepreneurs, the institution is considered a pioneer in the field of craft training.

Read more about them in their website here.

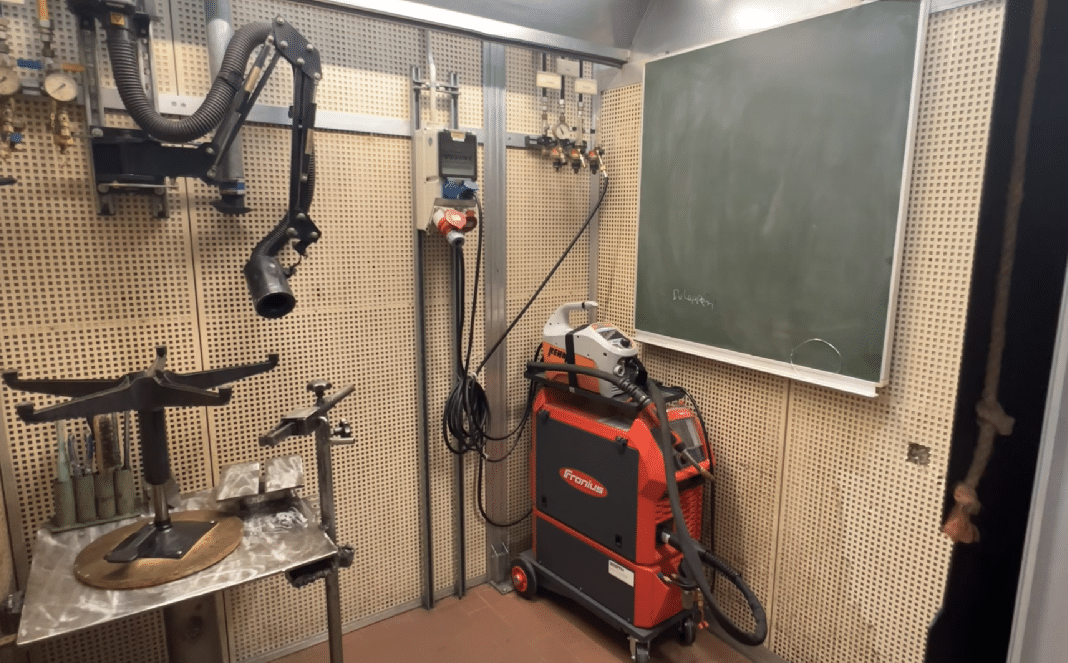

Bernd Tenschert, Sales Manager Germany and Sofie Zachariassen, responsible for marketing and sustainability at Inelco Grinders ®, were able to gain valuable insights into the training center from Matthias Fröhlich from Handwerkskammer Heilbronn-Franken. Here, numerous trainees and those willing to learn embark on their journey to learn the art of welding. Witnessing first-hand the meticulous training environment reaffirms the institution’s commitment to providing top-tier education.

The collaboration with Inelco Grinders ® goes beyond equipment; it is rooted in the shared belief that precision welding education requires not only cutting-edge tools but also an environment that fosters learning and safety. The tour highlighted the vital role of safe and precise equipment in shaping the next generation of skilled professionals. Handwerkskammer Heilbronn-Franken’s commitment to excellence in welding education shines through its state-of-the-art facilities, where students hone their craft under the guidance of experienced instructors.

Matthias Fröhlich, representing Handwerkskammer Heilbronn-Franken, provides insights into the institution’s unwavering dedication to safety, precision, and environmental responsibility, exemplified through the utilization of Inelco Grinders ®‘ Ultima-TIG®. Focused on occupational health and safety, the Ultima-TIG® ensures guaranteed safety during use, eradicating the risk of injury and inhalation of grinding particles due to the enclosed grinding chamber and dust collector.

The Ultima-TIG® stands out with its infinitely variable adjustment of the grinding angle and wet grinding accuracy, making it an ideal choice even for users with minimal prior knowledge. This is attributed to the precise grinding of Tungsten electrodes, which have seen a rise in costs. Thanks to the Ultima-TIG® Tungsten grinder, the need for re-grinding is minimized, due to its unparalleled precision. Additionally, fewer electrode ends are discarded, as the grinder allows grinding down to 8 mm, facilitated by the electrode holder. Additionally, the collection and recycling of grinding dust emphasize Handwerkskammer Heilbronn-Franken’s commitment to environmental protection.

Inelco Grinders ® envisions a transformative approach to the “New Normal” in the welding industry, urging welders to prioritize safety and sustainability over traditional viewpoints that accept injuries from grinding and welding as inevitable. The objective is to contribute to a paradigm shift within the welding community, elevating the importance of health, safety, quality, and environmental considerations. Encouraging the newer generation to advocate for a better work environment and demand safe equipment at their workplaces is at the heart of our mission. We continue to admire institutions like Handwerkskammer Heilbronn-Franken, whose work aligns with Inelco Grinders ®’ broader objective of fostering a welding culture that values the well-being of practitioners and the environment.

Watch the interview on YouTube: