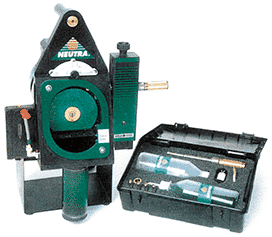

Neutra

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo the new normal in tungsten grinding.

Highlights

- Sealed grinding chamber with dust collector to protect the user

- Variable angle setting gives more flexibility

- Wet grinding prevents overheating of the electrode during grinding

- High grinding speed provides faster grinding and a smooth surface

- The electrode holder ensures centring of the tip and reduces wastage

- Less electrode wastage results in a short payback time

Descrição

Portable grinding machine for tungsten electrodes

Effective

NEUTRIX is a handheld and portable grinding machine that fulfills the equirements for safe and environmentally friendly grinding of Tungsten electrodes in high quality for TIG and plasma welding. Grinding in the longitudinal direction of the electrode, variable grinding angle, three grinding positions on the diamond disc and the electrode holder ensure efficient grinding.

Mobile and safe

The storage case and low weight make NEUTRIX ideal where there is a need to take the grinder with you. At the same time, the NEUTRIX, is equipped with an integrated dust filter that protects against the harmful grinding dust and collects the dust for safe disposal.

Short electrodes

NEUTRIX can grind electrodes down to lengths of 19 mm and even 15 mm with a special clamp, for example for orbital welding. The inspection cover on the grinder makes it easy to follow the grinding process and to ensure that the electrode is not generating sparks during grinding. This avoids the electrode being damaged by high temperatures.

Simple operation

Insert the electrode in electrode holder and lock it in the stick-out. Set the variable degree scale at the desired angle. Place the electrode holder in the grinder. Start the grinder and rotate the holder until it reaches the stop and the grinding isfinished.

Especificações

Grinder facts

Electrode size: Ø0.8 – 4 mm

Min. length: 19 mm standard (15 mm with special electrode clamps)

Angles: 7.5° – 90° grinding angle (equal to 15° – 180° tip angle)

Technical specifications

Motor: 110V-50/60 Hz, 220V-50/60Hz

Motor effect: 850W

Weight: 2.8 kg

Speed: 22,000 – 28,000 rpm

Grinding speed: 28 – 50 m/sec.

Standard unit includes

- Complete grinder with diamond disc, filter and storage case

- Electrode holder

- Electrode clamps for Ø1.6, 2.4 and 3.2 mm electrodes (clamps are available for other electrode sizes)

Extra accesories

- Foot for mounting on a work table

- Electrode clamps for all electrodes from Ø0.8 – 4.0 mm

- Electrode clamps for grinding extra short electrodes

Add-ons & parts

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Book a free demo

Our tungsten grinders reduces the use of tungsten electrodes by up to 50%. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

TIG welding applications

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Used for more than 30 years

35,000+ units sold

Used in numerous sectors

Produtos relacionados

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Entre em contato connosco

Tem qualquer pergunta sobre os nossos produtos ou outro assunto? Sinta-se à vontade para entrar em contato connosco através do formulário de contato, uma mensagem e-mail ou telefone diretamente para nós. Será um prazer entrar em contato consigo.