Inelco Grinders ® and WeldingDroid join forces to improve welding quality while increasing customer profit and efficiency

Inelco Grinders ® has many years of experience in the development, production, and sale of dry and wet grinders for grinding Tungsten electrodes used in TIG welding. As one of the world’s leading manufacturers of Tungsten grinders, their products are known for their unique quality, profitability, and precision.

WeldingDroid represents the latest innovation in welding automation, they use proprietary software to auto-generate perfect pipe, tube and tank welding every time. They develop and manufacture machines that address the problems that are often found in the pipe welding industry, e.g., the lack of skilled and qualified welders and pipefitters.

Automated welding means high welding quality, faster welding, and high-cost savings

“Using a WeldingDroid, you can increase productivity with 3-6 times faster welds. A stainless steel Ø406 × 3 is welded in less than 6 minutes, including 10 mm overlap. A stainless steel Ø960 × 2 is welded in 13 minutes, including an overlap of 10 mm. In addition, WeldingDroid X1 guarantees a uniformly high welding quality and there is no need for corrections of welding defects. ” – says Mikkel Falk, CEO of WeldingDroid.

In automated welding, it is a requirement that the electrode is uniform and precise to ensure the perfect conditions for the weld. Claus Brandborg, Sales Manager for Inelco Grinders ® says: “Inelco Grinders ®‘ guarantees precision grinding as well as an automated grinding process. It is especially important in automated TIG welding that the tip of the Tungsten electrode is centred.”

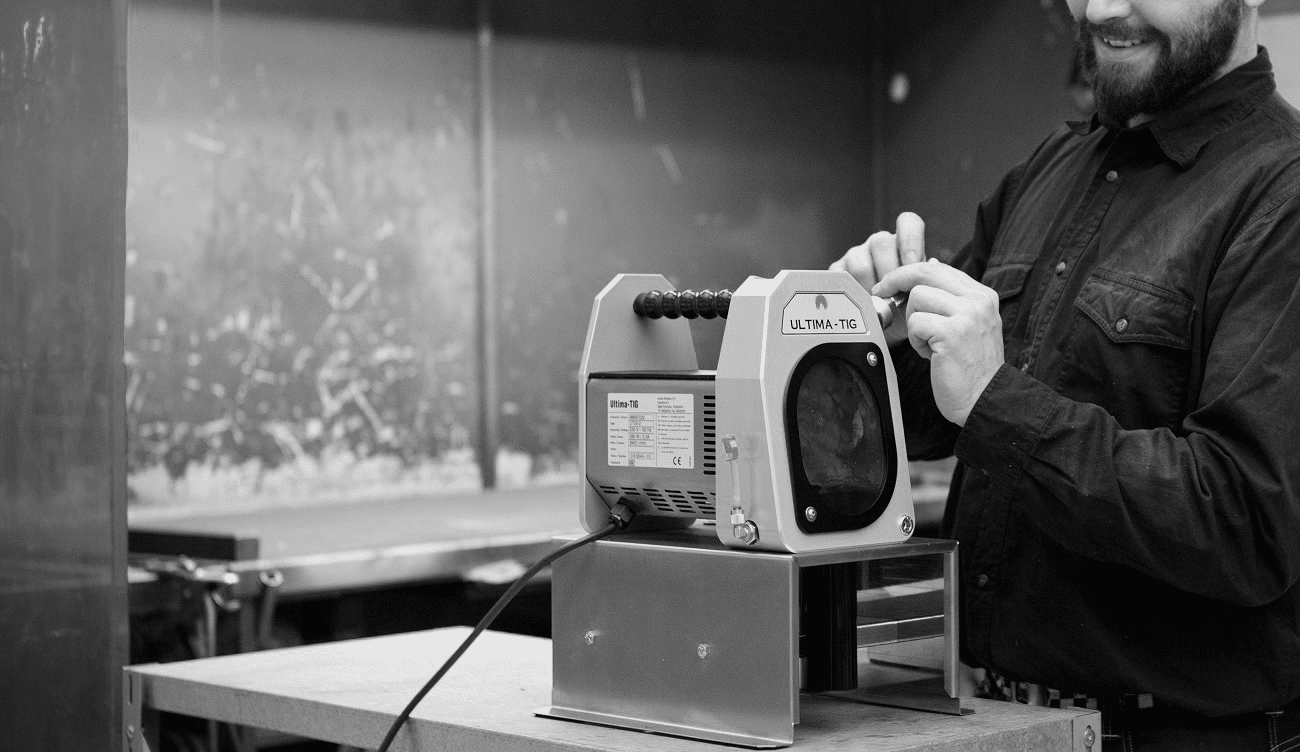

With Inelco Grinders ®‘ Ultima-TIG®, fast and uniform grinding of the Tungsten electrodes is achieved – every time. Ultima-TIG®-Cut can prepare electrodes of any desired length if shorter electrodes are needed for the automated welding.

Focus on efficiency, quality, and profitability

Both Inelco Grinders ® and WeldingDroid place an emphasis on making a positive contribution to the welding industry by focusing on high quality, efficiency, and profitability.

With Inelco Grinders ®‘ many years of experience, they offer Tungsten grinders that guarantee safe and accurate grinding of Tungsten electrodes. This improves welding efficiency and welding quality. In addition, they reduce the waste of expensive Tungsten electrodes and reduce the time spent on grinding, which ultimately ensures savings and increases profits. So their grinders pay for themselves.

For many years, welding pipes has been hard manual work with awkward working positions for many hours every day. By introducing WeldingDroid software as well as integrating power source, wire feed and machine learning into WeldingDroid’s intuitive user interface, they have eliminated cumbersome machine setup, allowing the operator to resize the tube in seconds. In addition, WeldingDroid guarantees even more benefits such as savings since it is not only skilled people who can weld when you make use of their automated welding, and you can experience a payback of less than 6 months.

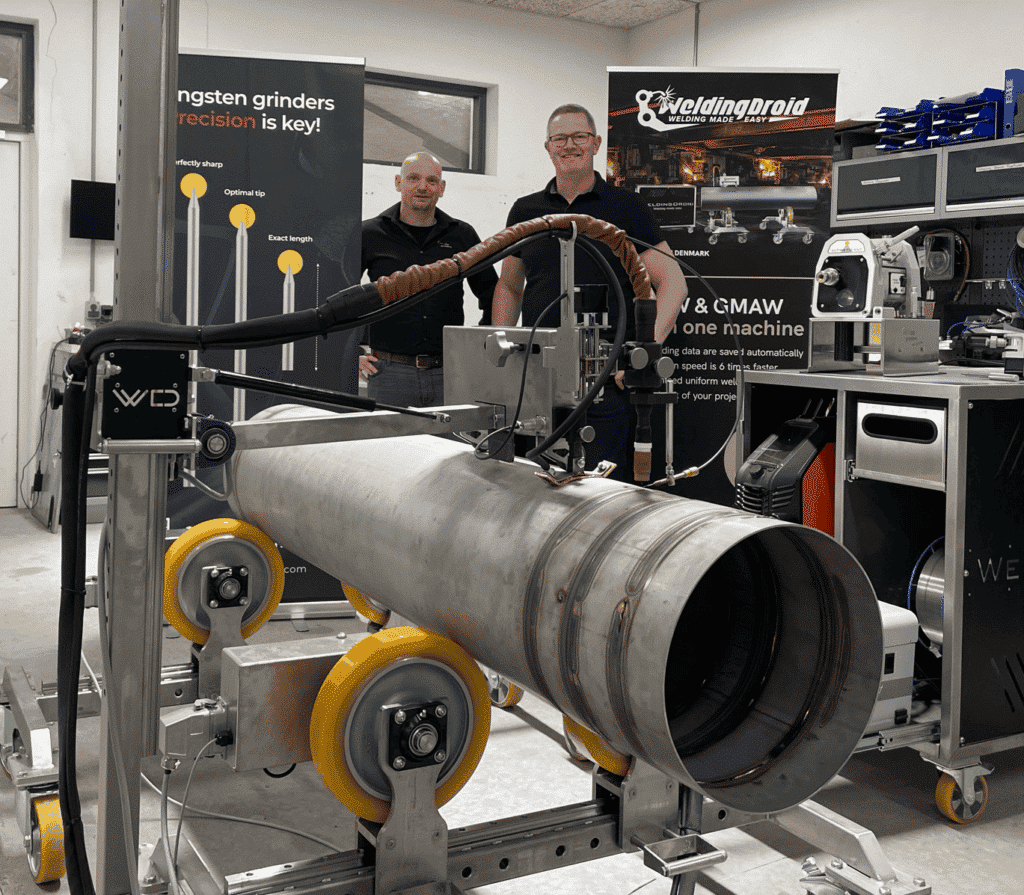

Meet them both at the Tube Tradefair in Düsseldorf – Stand number: 6F02

The fair will take place on 20 – 24 June 2022 in Düsseldorf, Germany. Come by and hear more about what they can do for you and how they can meet your welding needs. Do you work in TIG welding or pipe welding? – look past their stand in Hall 6 / F02. Here, Claus Brandsborg, Sales Manager at Inelco Grinders ® and Mikkel Falk, CEO at WeldingDroid give demonstrations and presentations of the machines.

Do not hesitate – get in touch or visit them at the fair on 20-24th of June!