Introduction

Cost-efficient safety

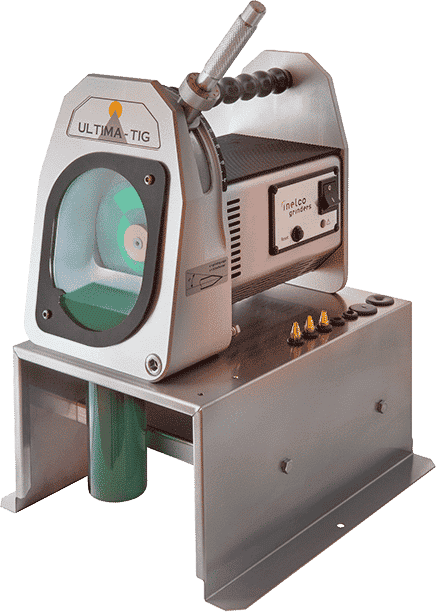

At Inelco Grinders we care about providing the best grinder possible that consequently creates the best conditions for the weld. Hence, we ensure accurate and precise grinding of the electrode for every weld. With our grinders you will experience less waste of the electrodes compared to waste from throwing out short electrodes, from lack of precision and from breaking off the tip after dip, which often are consequences of using open belt or bench grinders.

Using our grinders inevitably provide the welders with an improved and safer work environment, as our grinders reduce work accidents when grinding. Furthermore, due to the dust collector of the Tungsten particles, the welder avoids inhalations of the harmful particles, as well as facilitates safe disposal of the grinding particles.

With a solid position among the world’s leading manufacturers of Tungsten grinders, our products are renowned for their unique quality, profitability and precision. Furthermore, our products represent an operator-friendly and eco-friendly solution.

FAQ

We have gathered some of the most frequently asked questions and answers below. If you have any further questions, please get in touch with one of our skilled staff.

Is grinding Tungsten electrodes dangerous?

Why is consistency in grinding the electrode important?

At what angle can you grind Tungsten electrodes?

How much can I grind the electrode?

How much can I save on average per year?

Can I try an Inelco grinder before buying one?

What to do with the grinding dust?

An economical choice

Minimal waste means better economy

Tungsten electrodes that can be ground further down each time translate to savings on the bottom line. In other words: Inelco Grinders don’t just grind Tungsten electrodes, they also trim the top off of company expenses.

- Savings in electrode consumption means shorter return on investment

- A correctly ground Tungsten electrode has a longer service life

- Grinding shorter means less waste of expensive electrodes

Safety

Win for the workers – win for the company

Inelco Grinders offer safer and healthier working environment for the welders and a better economy for the companies – so why not benefit from more safety when it improves the economy?

Precision

Precision grinding – part of the secret

A good, durable and strong TIG weld has to be done right. To do this, it is important that the Tungsten electrode is ground precisely, otherwise, the weld will not be correct. Such precision requires experience and skill.

At Inelco Grinders, we are not good at keeping secrets, so we might as well tell it like it is: With a really good Tungsten grinder, you get both higher quality welds and cash savings.

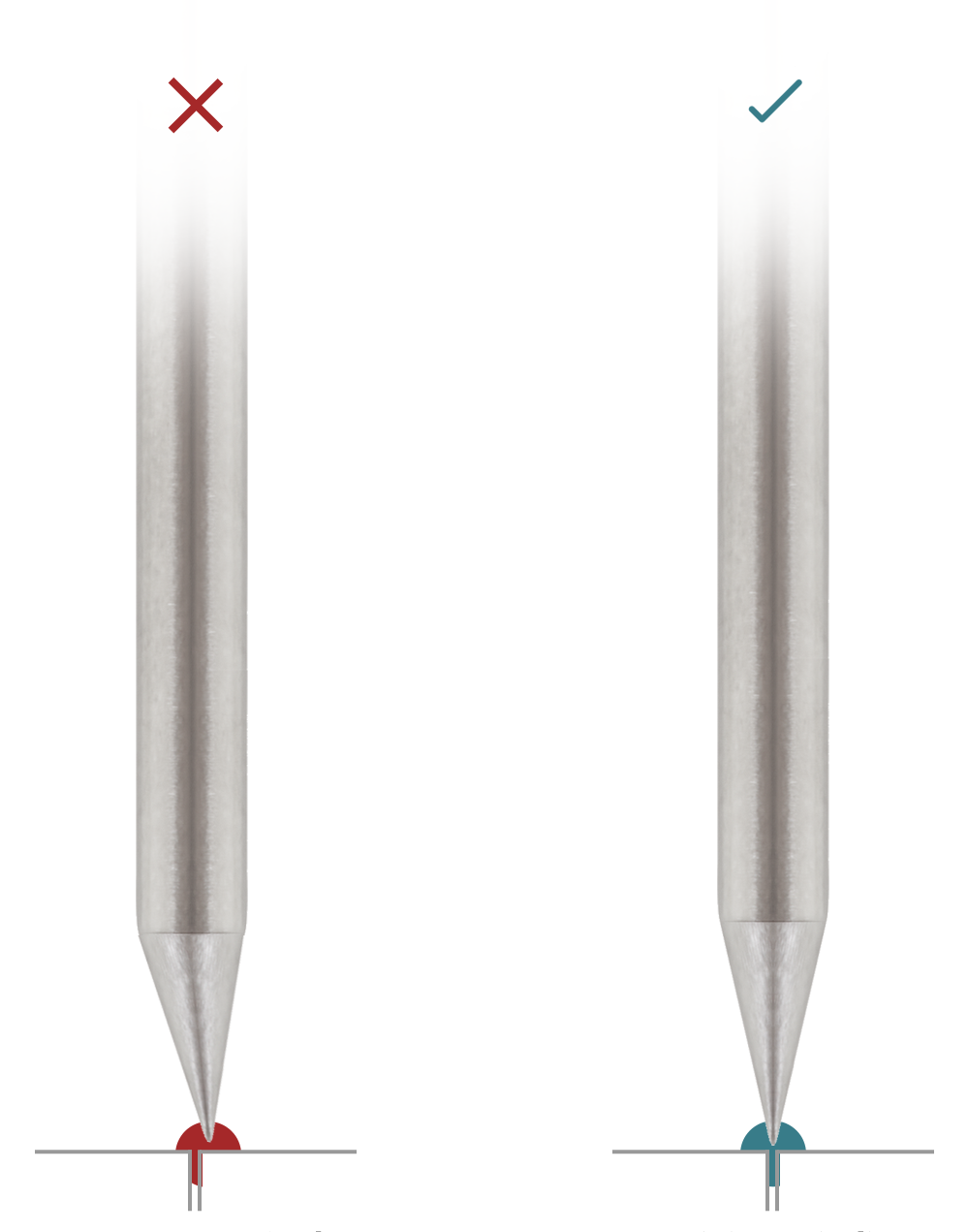

A non-centred tip does not ensure that the welding is in the exact right position

A centred tip ensures high and uniform quality of the weld

The environmentally

conscious journey

We contribute to sustainability

Inelco Grinders is becoming more environmentally conscious in which we aim to help our customers save natural resources in terms of the extraction and production of Tungsten, as it is considered to have an extensive and negative impact on the climate. Thus, we intend to examine possibilities of reducing our customers’ carbon footprint as well as our own.

Using our grinders minimises waste of Tungsten electrodes thanks to the precision of the grinding machines, as the loss with every regrind reduces considerably in comparison to hand grinding.

In addition to minimising the waste of Tungsten electrodes, all our grinders are equipped with a dust collector, which prevents the toxic grinding particles from polluting the environment and ensures safe disposal. We continuously strive to become more and more sustainable. Our first steps in reducing our own CO2 emissions involve reducing, sorting, and recycling our own waste. Going forward, all our development projects will have a focus on sustainability.

Book a free demo

Our Tungsten grinders reduce the use of Tungsten electrodes by up to 50%. Are you interested in evaluating how much you can save and how our grinders can meet your welding needs? Please enter your information below and we will ensure that the nearest distributor will contact you to find the best solution that suits you.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.