Dust collector

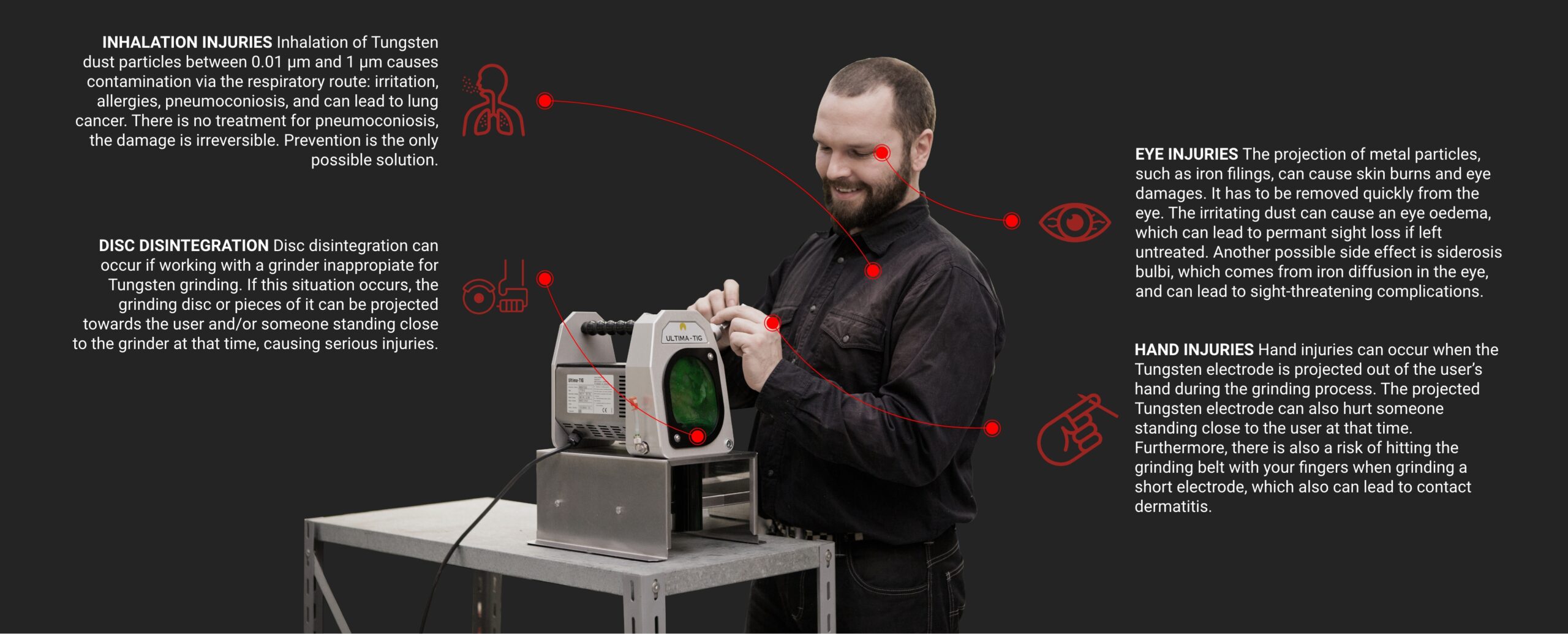

It is important to dispose of the Tungsten dust correctly. This is because potential inhalation and intake of Tungsten particles can not only occur during the grinding process with a grinder without dust collection, but also because of handling and improper disposal of the grinding dust.

Other Tungsten grinders without correct gathering of the grinding dust require sweeping it off the floor or even if using an extraction system there is a risk when handling the filter. With the Ultima-TIG® dangerous handling of the dust can be avoided and with the dust collector this process is made easier.

Enclosed grinding chamber

At Inelco Grinders®, we care about the health and safety of the welder and have therefore developed the Ultima-TIG® with an enclosed grinding chamber to guarantee prevention of accidents as well as health implications due to inhalation of Tungsten dust. Dust particles of all sizes between 10 μm – 0.01 μm are present in the air during grinding of electrodes. The really dangerous particles are those smaller than 0.1 μm as they cannot be excreted by the body due to their size or shape and therefore remain in the body, also referred to as nanoparticles. Additionally, due to the enclosed grinding chamber the grinding can take place with a specifically designed cooling liquid to avoid overheating of the electrode.

Electrode holder

Grinding Tungsten electrodes without protective gear poses risks, including metal projections, accidents, burns, and contact dermatitis.

However, using protective gloves may lead to accidents and limit grinding length. The electrode holder eliminates these risks by securing the electrode, preventing accidents and allowing safe grinding down to 8 mm.

White paper

Sign up for our newsletter and get a free white paper on ‘Tungsten electrodes’ impact on health & safety’ 12 pages explaining the high risks of grinding Tungsten electrodes and how to avoid them.