Tungsten Grinder for Professionals

Ultima-TIG®

Ultima-TIG® is our wet grinder of Tungsten electrodes that ensures precise grinding at the correct angle and perfect centring of the tip of the electrode. It grinds down to 8 mm which results in minimal electrode waste.

Highlights

- Sealed grinding chamber with dust collector to protect the user

- Variable angle setting gives more flexibility

- Wet grinding prevents overheating of the electrode during grinding

- High grinding speed provides faster grinding and a smooth surface

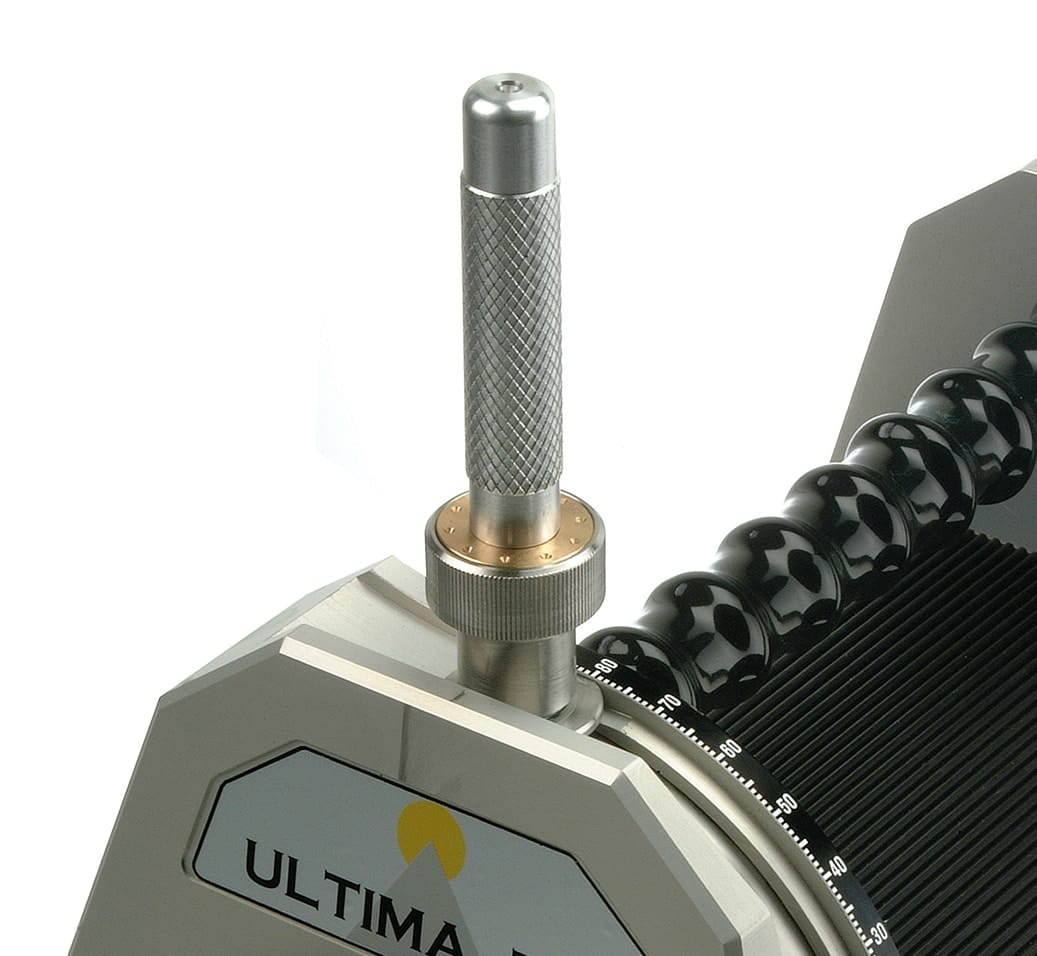

- The electrode holder ensures centring of the tip and reduces waste

- Less electrode waste results in a short payback time

Description

High-quality Tungsten electrode grinding

Environmentally friendly and safe

Ultima-TIG® is the environmentally friendly wet grinder of Tungsten electrodes for TIG welding, with minimal wastage of the expensive electrodes. Ultima-TIG® is constructed with a unique disposable container that automatically collects the toxic dust particles and ensures safe disposal.

Cost-effective in high-quality

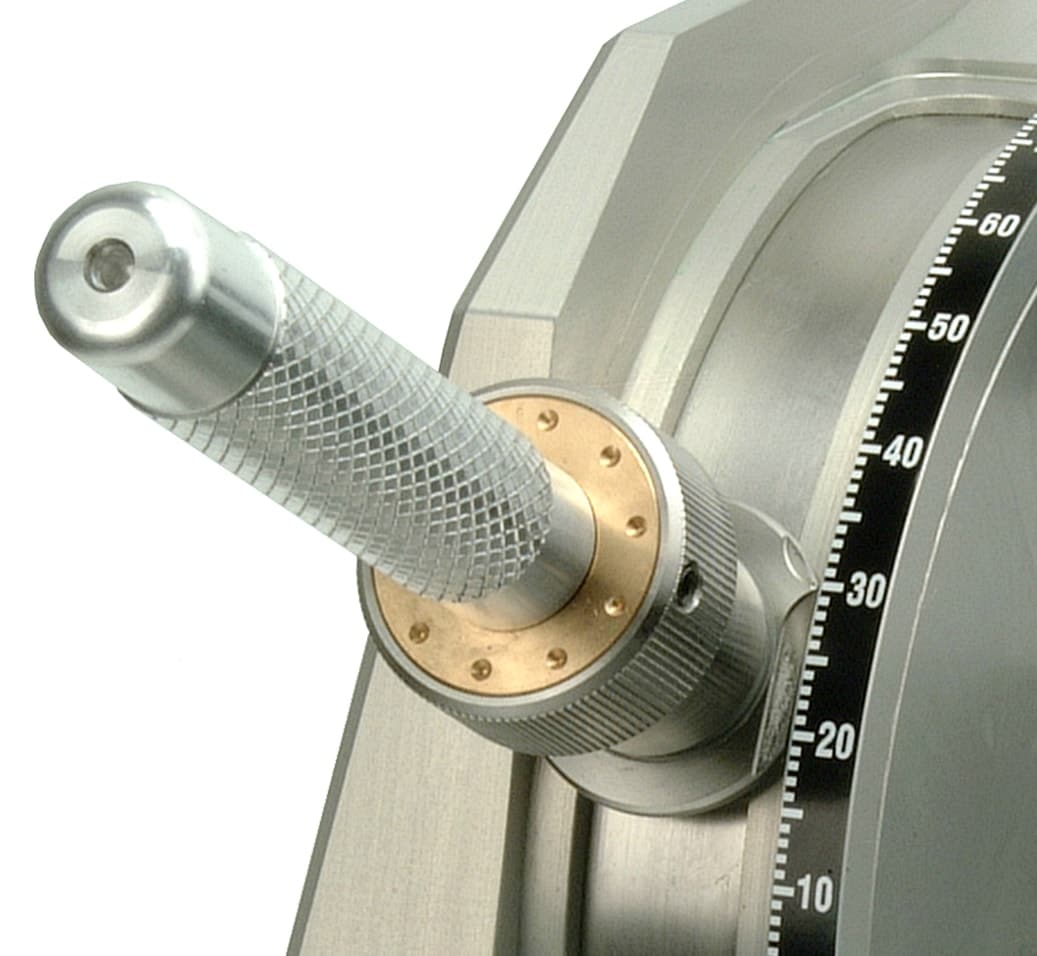

Ultima-TIG®’s unique construction reduces the waste of expensive Tungsten electrodes and reduces the time spent on grinding, resulting in a short payback time. The variable angle adjustment and unique clamping system centres the electrode, so that the grinding is carried out in the correct longitudinal direction of the electrode. A precise angle is not only important for the quality of the welding seam; the number of re-ignitions between re-grinding is also increased.

Wet grinding

The combination of liquid for cooling and a high grinding speed of the diamond disc results in a polished and even surface of the Tungsten electrode. In addition, the cool wet grinding shortens the grinding time and prevents overheated and damaged electrodes.

Simple operation

Set the variable angle setting at the desired angle. Place the electrode in the electrode holder and tighten it in the stick-out. Insert the electrode holder, turn on the grinder and rotate the electrode holder until grinding is finished. After grinding, flatten the tip by placing the angle adjustment in the 90° position, if needed.

New engine control with

- Service indicator

- Overload protection

- Readout the number of grindings

Downloads

Specifications

Grinder facts

Electrode size: Ø0.8 – 4 mm

Min. length: 15 mm standard (8 mm with special clamps)

Angles: 7.5° – 90° grinding angle (equal to 15° – 180° tip angle)

Technical specifications

Motor: 110V-50/60 Hz, 220V-50/60Hz

Motor effect: 280W

Motor speed: 6000 rpm

Grinding speed: 31 m/sec.

Standard unit includes

- Grinder complete with table, diamond disc and grinding liquid

- Electrode holder

- Electrode clamps for Ø1.6, 2.4 and 3.2 mm electrodes (clamps are available for other electrode sizes)

Ultima-TIG® is CE marked and meets all current EU regulations

Add-ons & parts

The add-ons are made to fit all our grinders in the Ultima-TIG® series. Furthermore, they have been developed due to demand for an automated grinding process and for truncating the tip of the Tungsten electrode. Here, it should be noted that various Truncator and AutoGrind Digital add-ons fit the equivalent grinder, for instance Truncator S and AutoGrind-S Digital fit Ultima-TIG®-S.

If you want to see the parts to our Ultima-TIG® that can be ordered separately, please go to our parts page. Here you can find parts and accessories for instance work table and grinding console, presented as a list with photos and their respective item number and description.

Book a free demo

Our Tungsten grinders reduce the use of Tungsten electrodes by up to 50%. Are you interested in evaluating how much you can save and how our grinders can meet your welding needs? Please enter your information below and we will ensure that the nearest distributor will contact you to find the best solution that suits you.

TIG welding applications

Our grinders are developed to accommodate the various ways of TIG welding to always ensure a safe, easy, efficient and consistent grind of the Tungsten electrode as it is important that the tip is centred.

Used for more than 20 years

35,000+ units sold

Used in numerous sectors

Related products

See our other products that may meet your welding needs.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.