Blunt the Tungsten electrode

Truncator

The Truncator module was developed in order to avoid the 2 situations that really stress your Tungsten electrode, when TIG welding. Those situations are high amperage welding and AC welding e.g., aluminium. In both situations you can diminish the risk of melting off the tip by truncating your Tungsten electrode.

Highlights

- Precise truncation of ground Tungsten electrodes

- Various positions on the grinding disc

- Eliminates the risk of melting off the tip into the weld pool, causing contamination

- Ideal for AC welding where it reduces the risk of obtaining an excessive ball at the tip

Description

Precise truncating of ground Tungsten electrode tips

New Truncator module

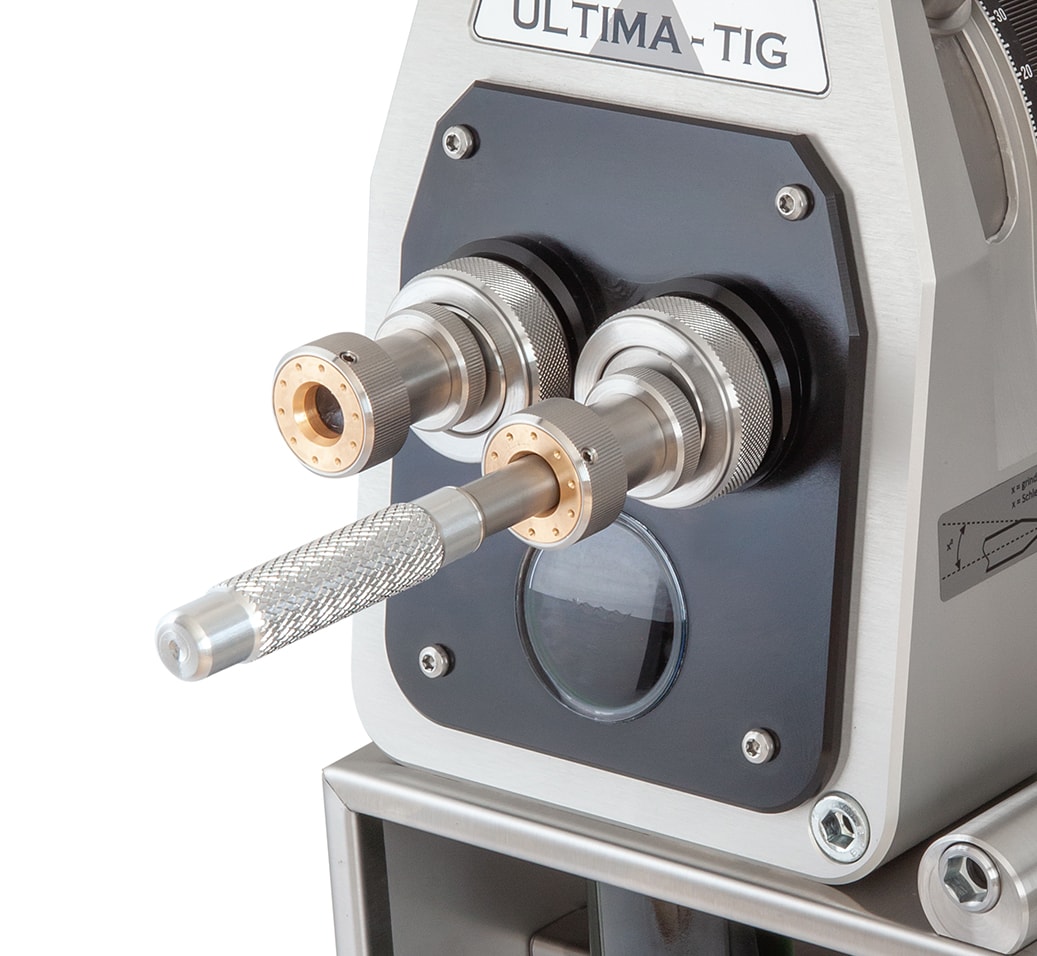

Our new Truncator is a separate module, designed and engineered for truncating of ground Tungsten electrodes for TIG welding. The new Truncator module can be mounted on our well-known Ultima-TIG® and Ultima-TIG®-Cut grinders. Besides we offer a special version for Ultima-TIG®-S.

Easy to use

- Grind an electrode tip on your Ultima-TIG®.

- Loosen the electrode from the electrode holder and secure it in the adjustment for the Truncator

- Insert the electrode holder in the Truncator.

- With the grinder switched on, press the electrode holder in to truncate the electrode tip.

- Switch off the grinder and remove the electrode from the electrode holder.

The size of the truncated tip can easily be adjusted to any desired diameter.

Special double module with two positions is available, if there is a need for two different electrode tips.

The Truncator also works with AutoGrind Digital mounted on the Ultima-TIG®.

For better welding results

There are mainly two reasons to truncate the tip of the freshly ground electrode.

- In high-current applications, the truncated geometry eliminates the risk of melting off the tip into the weld pool, causing contamination.

- In AC applications, the truncated geometry reduces the risk of obtaining an excessive ball at the tip. Knowing that an excessive ball causes an unstable arc and might fall and contaminate the weld.

NOTE!

For mounting on older versions of Ultima- TIG/-S/-Cut (serial no starting with 2036 or lower) you need two extra holes on the front of the grinding module. A toolset with drill and thread tap or a new grinding console can be ordered with the following item numbers:

| Item No | |

| Toolset with drill and tap | 75523030 |

| Grinding console | 44520000 |

| Grinding console complete | 75523020 |

Specifications

The Truncator module includes

- Truncator module

- Grinding disc for truncating

- Grinder mounting screws (for mounting on the grinder)

| Grinder Model | Truncator | Item No |

| Ultima-TIG® | Single | 75523010 |

| Ultima-TIG®-Cut | Single | 75523010 |

| Ultima-TIG®-S | Single | 75523011 |

| Ultima-TIG® | Double | 75523012 |

| Ultima-TIG®-Cut | Double | 75523012 |

| Ultima-TIG®-S | Double | 75523013 |

Parts

If you want to see the parts to our Truncator that can be ordered separately, please go to our parts page. Here you can find parts and accessories for instance grinding disc and the frame. Here is a list with photos and their respective item number and description.

Book a free demo

Our Tungsten grinders reduce the use of Tungsten electrodes by up to 50%. Are you interested in evaluating how much you can save and how our grinders can meet your welding needs? Please enter your information below and we will ensure that the nearest distributor will contact you to find the best solution that suits you.

TIG welding applications

Our grinders are developed to accommodate the various ways of TIG welding to always ensure a safe, easy, efficient and consistent grind of the Tungsten electrode as it is important that the tip is centred.

Used for more than 20 years

35,000+ units sold

Used in numerous sectors

Related products

See our other products that may meet your welding needs.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.