Introduction

Inelco Grinders A/S focuses on the development, manufacture and sale of Tungsten electrode grinders that are primarily used for TIG welding.

We were originally part of Inelco A/S, but in a bid to sharpen focus on Tungsten electrode grinders, Inelco Grinders A/S was founded on 1 January 2010. Our aim is to boost our leading position on new and existing markets with Tungsten electrode grinders and to develop our business area within this sector.

We have many years of experience of both dry and wet grinding of Tungsten electrodes, and today we enjoy a solid position on the market with dealers all over the world, as well as collaborating with some of the largest manufacturers of welding equipment. With our products, we aim to boost the quality of TIG welding with perfectly ground electrodes, yet at the same time we wish to contribute to health and safety at the workplace by ONLY offering Tungsten electrode grinders to the welding industry that are safe and not harmful to the health of the employees working in the industry.

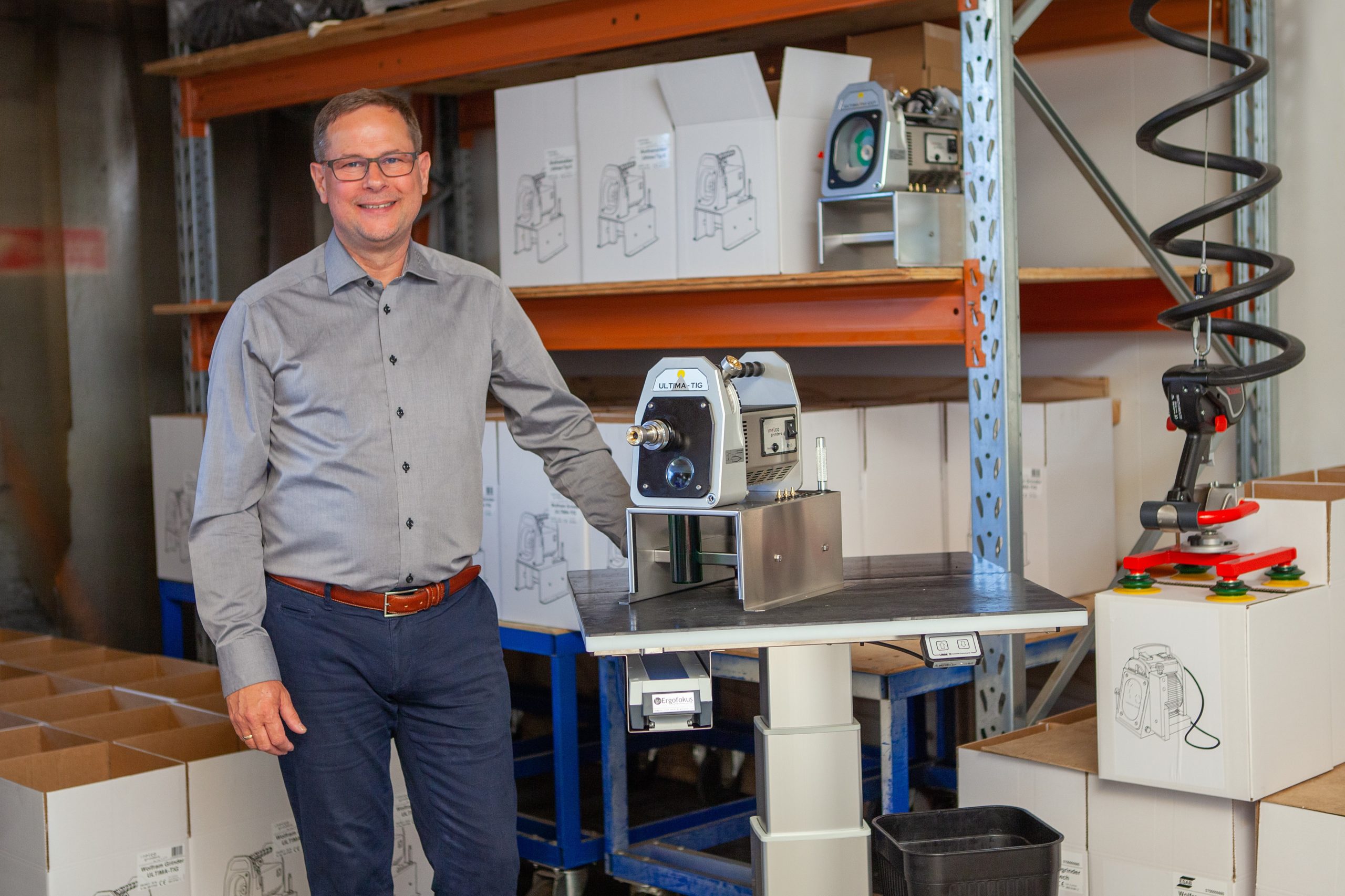

Anders Thy, CEO Inelco Grinders A/S

Available world wide

Throughout the years, Inelco Grinders A/S has expanded its net of distributors and we pride ourselves on our great collaborations with them. Relationships with new dealers are continuously being built all over the world through great cooperation and trust. Our long-term partnerships have formed through common goals based on continuous desire to grow and contribute to sustainable innovation. The dealer network is currently over 55 countries and across all continents. It is important for us that our dealers possess great knowledge of, and are specialised in, the welding industry with the purpose of advising and selling to our clients as to identify and meet their needs.

To get in contact with one of our excellent distributors in a location closest to you, contact us and we will redirect to our sales representative responsible for the respective market. Our skilled dealers can also give a free demonstration of our grinders.

45,000+ units sold

Sold across all continents

What drives us

3 clear values

- We contribute to sustainability

- We are innovative

- We partner up with distributors

Our history

Throughout our more than 20 years of experience, quality has been at the heart of everything we do. Learn how Inelco Grinders has become the leading designer and manufacturer of Tungsten electrode grinders.

1979

Inelco A/S was born

Inelco Grinders A/S was born out of Inelco A/S, a Danish electronics company. Inelco A/S started in 1979 and made heaters and battery chargers.

2001

Neutra was acquired.

Inelco A/S acquired the Neutra grinder, which came on the market in the early 1990s, becoming the first grinder that Inelco A/S has sold.

2001

Neutrix launched

Neutrix, the handheld and portable grinding machine, came out. It was introduced to meet the need for a safe and mobile grinder, with a light weight and with an integrated dust filter that protects the welder against the dust particles.

2003

Ultima-TIG was introduced to our clients

Our well-known wet grinder Ultima-TIG was launched with the purpose to expand our product range and further develop the Neutra grinder to a more user-friendly grinder with easier angle adjustment. Ultima-TIG embodies the main qualities of being environmentally friendly, excretes minimal waste of electrodes and it collects the toxic grinding particles.

2008

Record year for partnerships

The export accumulated to 75% of the turnover and many distributers around the world joined us. Furthermore, the export had expanded to 25 different countries.

2009

First sight of Inelco Grinders A/S

By the end of December Inelco Grinders A/S was founded, giving the opportunity to focus solely on wet tungsten grinders and in January 2010, Inelco Grinders A/S acquired all the activities involving the Tungsten grinders from Inelco A/S. As head of the company, Anders Thy owns 1/3 of Inelco Grinders A/S. The rest is divided between the then owner of Inelco A/S and the chairman of the board.

2010

The Ultima-TIG line is expanding

This was the year that the Ultima-TIG line was expanded resulting in the release of Ultima-TIG-Cut due to demand of both grinding and cutting of Tungsten electrodes. It features safe cutting of the electrode without splitting it as well as precise wet grinding, which also results in less electrode waste.

2015

Welcome to our add-on AutoGrind Digital

Due to the demand of a more automated grinding process, Inelco Grinders A/S, in collaboration with a major luxury car manufacturer, introduced Autogrind, an add-on for Ultima-TIG. The car manufacturer does automated welding; hence they require that the quality of the grinding is top notch. Their pre-ground electrodes only had a service life of 30% after regrinding, now using Ultima-Tig-Cut with AutoGrind, their electrodes reach a 100% service life, resulting in great savings and greater efficiency.

2016

Inelco Grinders A/S has a presence in 40 countries

Inelco Grinders A/S managed to achieve the presence of distributors in 40 different countries, by maintaining great relationships with our amazing partners.

2018

Anders Thy owns the entire Inelco Grinders A/S

Anders Thy buys out the two other owners, thus owning 100% of Inelco Grinders A/S. Additionally, Inelco Grinders A/S collaborated with another big customer through a dealer in 2018 in France. This customer invested in 18 Ultima-TIG-Cut and 12 Neutrix, as Inelco Grinders A/S meets their needs of safety, health, environment, quality, and productivity. The return on their investment is 18 months due to savings on the electrodes.

2019

Inelco Grinders can now be found in 50 countries.

Inelco Grinders A/S is proud to announce that our distributor network has reached 50 countries, due to our great partnerships around the world.

2020

Further expansion of export and distributors

85% of turnover is now exported and the distributor network has increased to 55 countries around the world. We a proud to also say that we further improved upon our existing relationships with our dealers.

2021

Our new add-on the Truncator, is released

Our Truncator debuted as a separate module, designed and engineered for the Ultima-TIG series to truncate ground Tungsten electrodes for TIG welding. Inelco Grinders A/S understands the importance of truncating, as it diminishes the risk of melting of the tip, it hereby preserves the tip as well as a stable arc and further extends the amount of time between regrinds.

2022

We are moving to a different building

Since we are expanding every year, we are in need of more space. Therefore, we are moving to a bigger office space where we will organise the production, warehouse, and the shipment area in a more practical manner. We expect to be expanding even more in the future! Our new address is Klokkestøbervej 4, 9490 Pandrup.

Research & Development

At Inelco Grinders we never stop challenging ourselves to create better grinders. We take pride in delivering premium quality in everything we do. We innovate the future making it the New Normal.

We continue to optimize the whole TIG welding process and to innovate and improve the grinders and our position in the market. It is important to us that our grinders are amongst the best on the market, hence the grinders are developed with a focus on safety as well as making them operator-friendly, with low environmental impact and high profitability. Our customers experience general and appreciable savings on the Tungsten electrodes themselves, and in terms of time spent on the grinding process.

In our development projects, one of our focal points have been the health of the welder. It can be harmful for the welder when grinding the Tungsten electrodes on traditional open belt or bench grinders as the harmful Tungsten particles are dispersed in the room and can end up in the welder’s lungs. Our dust collector ensures safe containment of the particles and thus secure disposal thereof. We take pride in this project, as it reduces our customers environmental footprint and ensures safe working conditions.

Moreover, we commit and pledge to contribute to the sustainable agenda while we strive to continuously advance our grinders taking health & safety, quality & efficiency as well as profit & savings into account.

Purpose & Values

From our mission, we draw the company’s core values, expressed in three main sentences:

We contribute to sustainability

We produce products and solutions that help our customers save natural resources and reduce climate impact. We take care of our people – and welders worldwide.

We are innovative

We are very much aware of the need to be innovative, driven by engineering and striving for constant development in products and solutions. Only in this way we can be a truly visionary market leader. To stay visionary, we must stay in motion, open-minded and knowledge based.

We partner up with distributors

A good partnership is based on commitment, openness and trust – and the ability to stay focused on common goals. We are building on long term relationships with our distributors and believe that diversity drives innovation and growth.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.