Contacts

Looking for someone specific? We have listed our key contacts below.

Administration

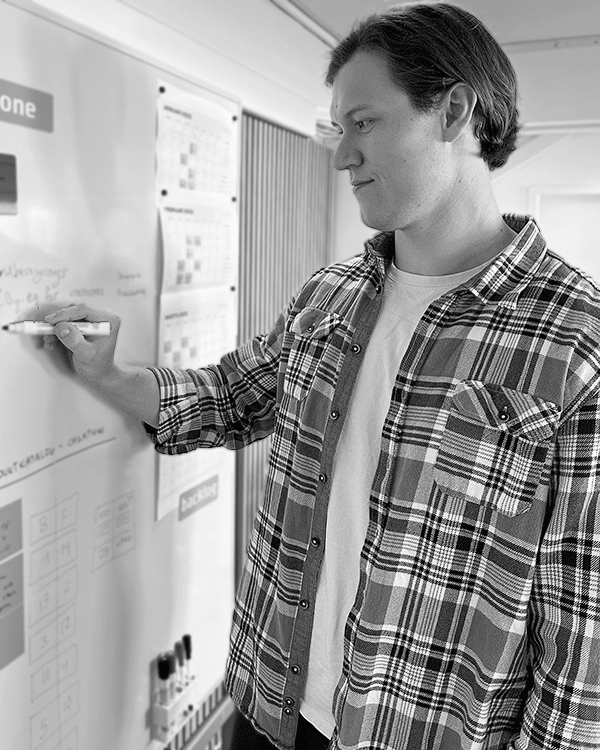

Thomas Maansson Lund

System Administrator IT and Sustainability

Sales

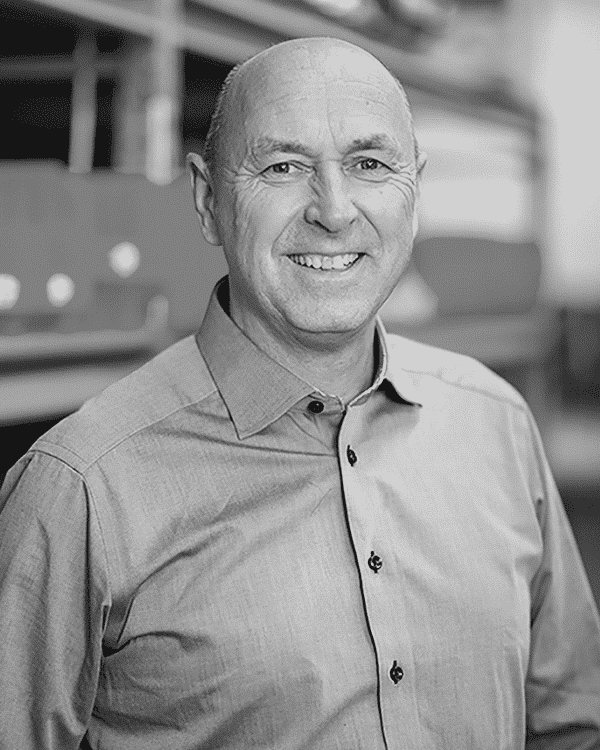

Claus O. Brandsborg

Sales manager of Scandinavia, Benelux, Central and Eastern Europe and Asia

Internal sales

Research & development

Purchasing, logistics & production

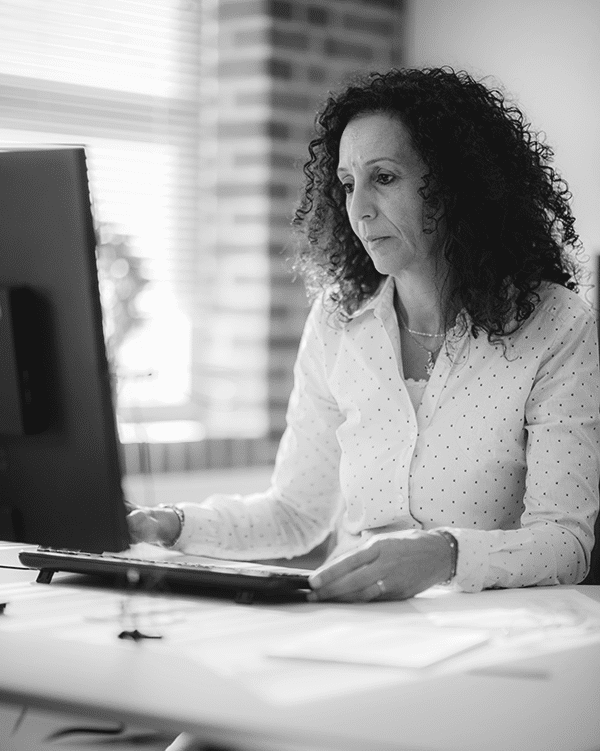

Weldetinsae Tekie Ghebremeskel

Warehouse

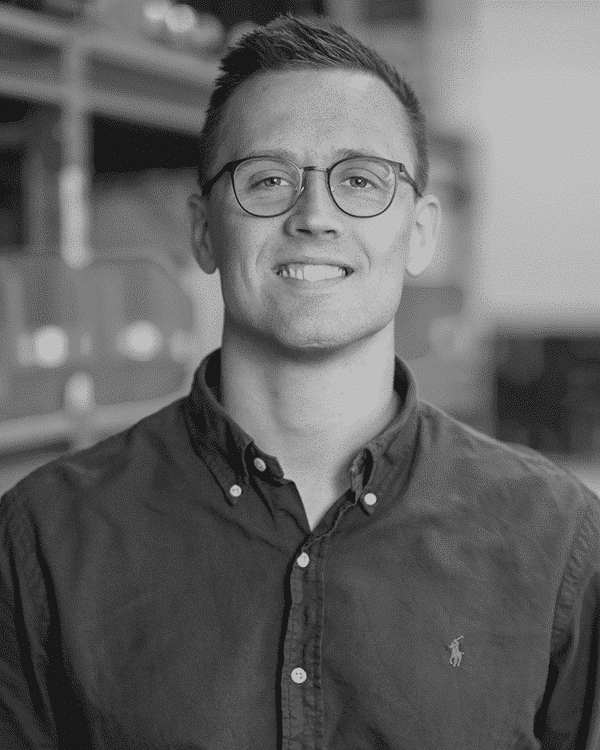

Bjarne Dahl Henriksen

Production

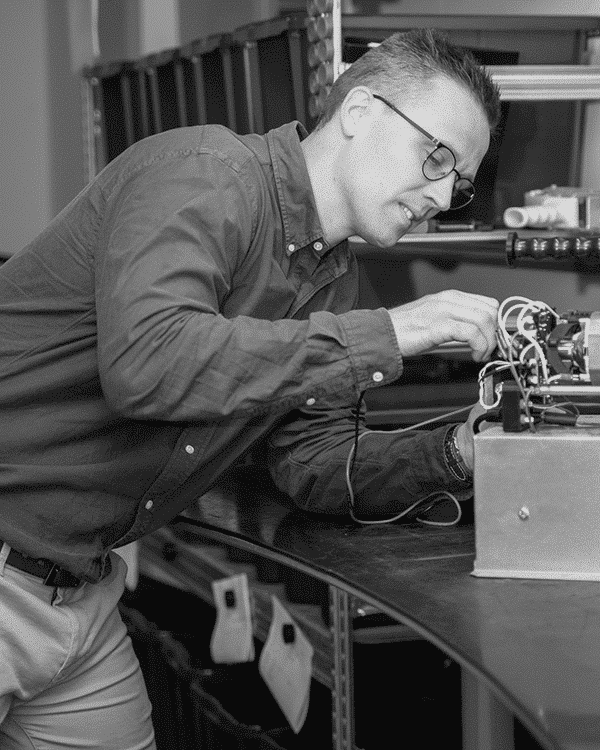

Mikkel Bruun Nicolaysen

Production

Marketing & sustainability

Sofie Klitgaard Zachariassen

Marketing & sustainability manager

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.