Health and safety awareness

The annual World Day for Health and Safety at Work on 28 April promotes and raises awareness of the prevention of occupational accidents globally. It is a campaign intended to bring international attention on the magnitude of the problem and on how promoting and creating a work culture that focus on health and safety can help reduce the number of work-related deaths and injuries.

This day is very important to us as “health and safety” has always been a core value for us, and is one of the 4 icons we stand by.

We want to challenge the traditional grinding process of Tungsten electrodes and therefore encourage welders to consider safety as well as sustainability and move away from the traditional viewpoint, where scars from grinding and welding are generally accepted as a matter of course.

Risks during grinding process

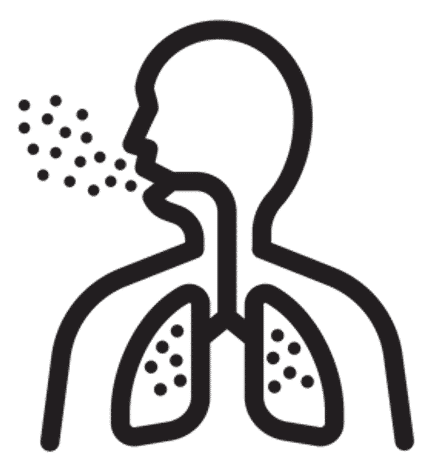

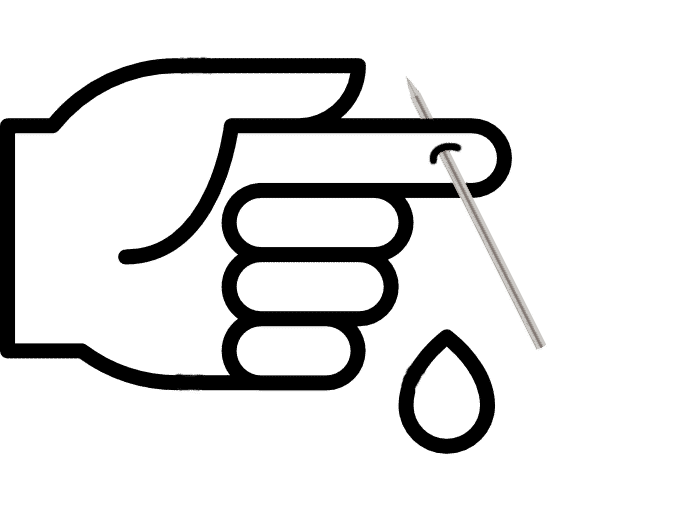

Many welders still use open bench or belt grinders to sharpen and cut their Tungsten electrodes. In doing so, welders are exposed to toxic dust inhalation, projection of metal particles and a high risk of injuries like fingers getting caught by the grinding wheel or belt, or the Tungsten electrode being projected out of the user’s hand and hurting the user or someone close by. The shorter the electrode, the higher the risks of contact with the grinding disc during the grinding process.

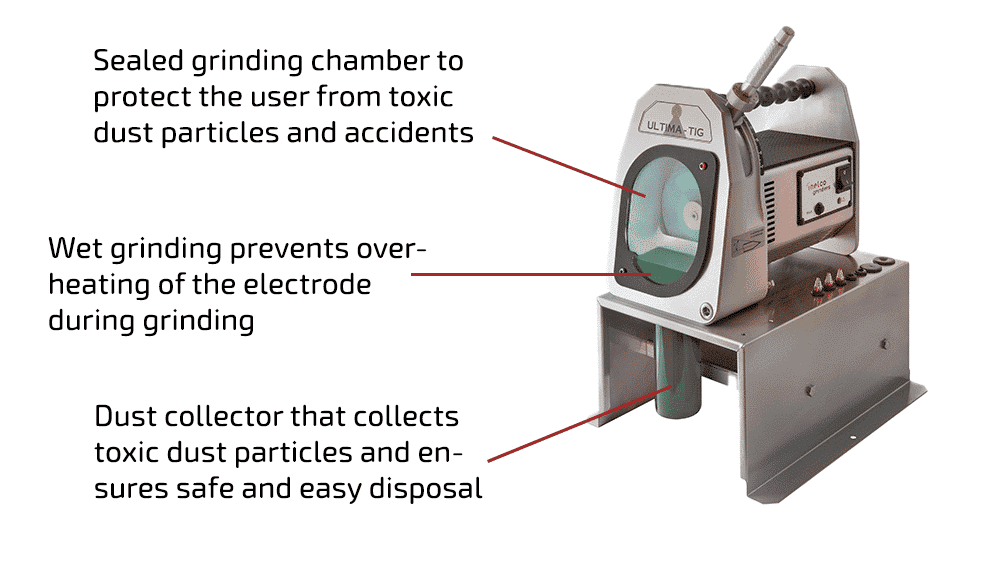

Our grinders minimises the risks

Due to the enclosed grinding chamber on our Ultima-TIG® the user can avoid accidents such as hand injuries because direct contact with the grinding disc is avoided. Projection of metal particles that can cause skin burns and eye damages is prevented with our safe grinders. Furthermore, inhalating the Tungsten dust particles can cause contamination via the respiratory route : irritation, allergies, pneumoconiosis. This too is avoided due to the enclosed grinding chamber as well as the dust collector.

In order to ensure the best possible results within a healthy and safe work environment, we continue to develop proper equipment for the welding industry so that everyone can go to work without fearing for their health. We believe that all risks can and must be avoided in any welding environment.

Read more about the benefits of using the Ultima-TIG®.

IMPORTANT: When possible, always choose a tool that can provide you with the best health and safety conditions, such as a secure Tungsten grinder for the grinding of your Tungsten electrodes.