At Inelco Grinders ®, we have started our sustainability journey last year, with the purpose of educating ourselves and evaluating our next steps in a more green and more sustainable world.

Last year, we have been accepted to be a part of a Danish sustainability project called “GCO” (concerning the conversion to a green and circular business model).

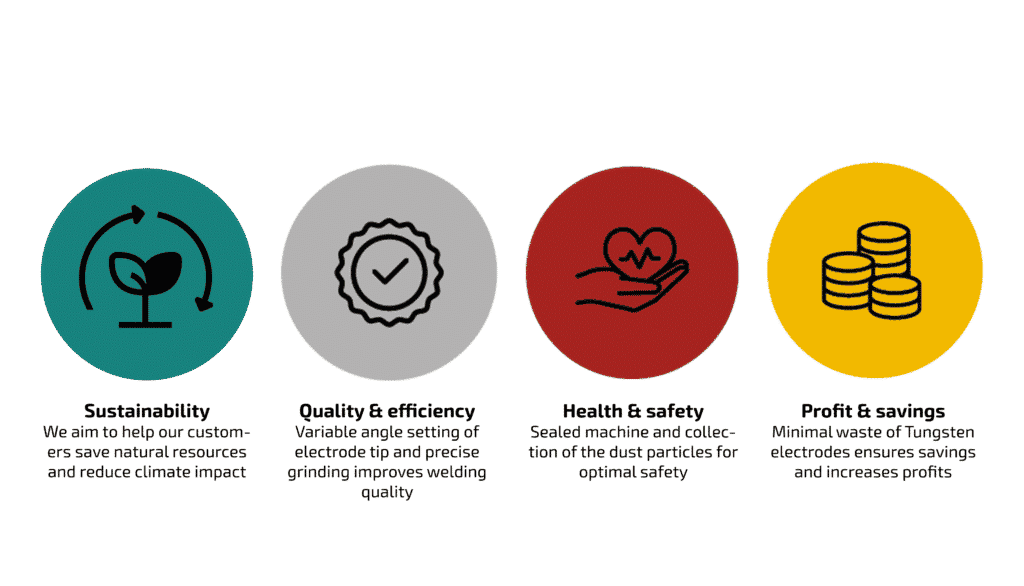

We want to reduce our own carbon footprint and contribute positively to the sustainable agenda. Furthermore, our intention is to help our customers save natural resources in terms of the extraction and production of Tungsten, as it is considered to have an extensive and negative impact on the climate. Thus, we intend to examine possibilities of reducing our customers’ carbon footprint as well as our own.

Green focus areas

In this journey, we realise how important transparency is and we therefore want to take you with us to show you each step of the way. Currently, we have the following focus areas that we are working on:

- Reducing our own carbon footprint

- Making our Ultima-TIG® more environmentally friendly

- Development projects going forward must include our new focus on sustainability

- In regard to reducing our own carbon footprint, we are talking with suppliers in order to make a calculation of our current CO2 emissions. Additionally, we have already taken the first steps by looking at reducing the amount of waste we produce and recycle the rest of that waste.

- Our Ultima-TIG® is already one of the most environmentally friendly Tungsten grinders on the market. This is due to the enclosed grinding chamber and the dust collector that prevents the toxic grinding particles from spreading and polluting the environment because it ensures safe disposal of the Tungsten grinding dust. Moreover, we are looking into possibilities that can reduce the carbon footprint of the Ultima-TIG®.

- Additionally, we want to make a commitment, where we in all future decisions keep a focus on sustainability for instance packaging, supplier’s and distributor’s values etc. as well as always learning and researching sustainable and eco- friendly opportunities to keep bettering ourselves and to minimize our environmental impact.

Hence, to represent our sustainability journey, we are introducing a new icon that will embody these new intentions. This icon will be presented together with our other 3 important focus areas, that you may already know:

We will continuously update you about our journey here on the blog and on our social media accounts. Follow us on: