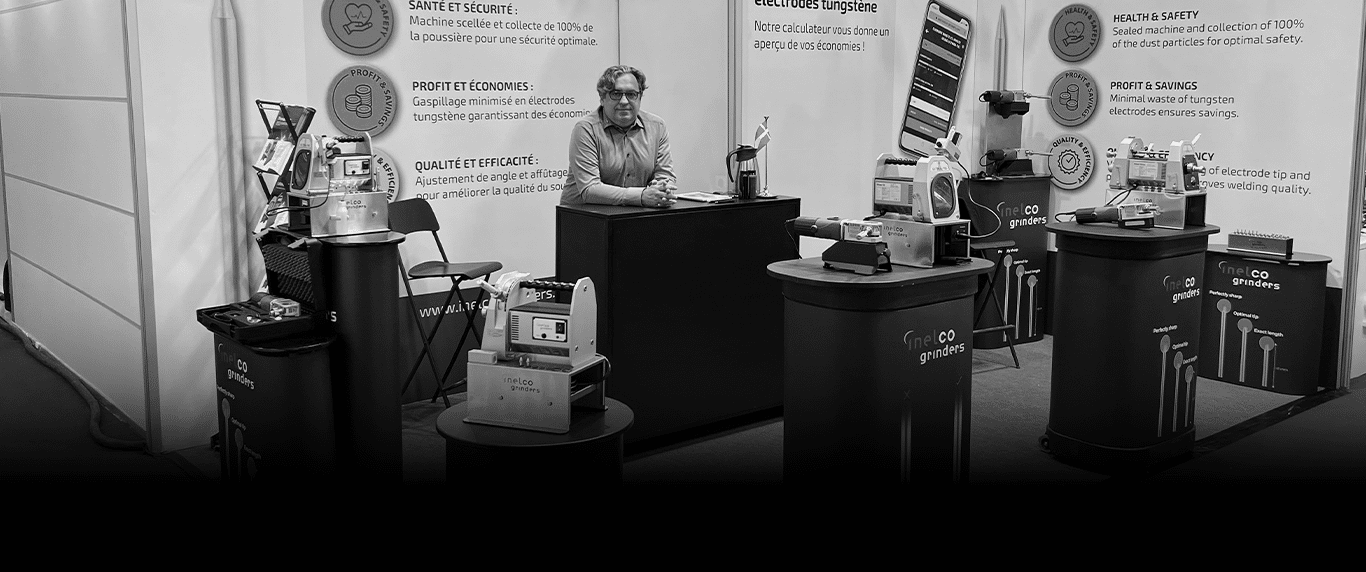

On the horizon awaits one of the most exciting industrial events of the year, the HI Trade Fair in Herning, Denmark. This year, we at Inelco Grinders ® have decided to participate in this significant event, where we will showcase our grinders and their precision grinding technology at stand C2556. A special focus will be on the Ultima-TIG® series, along with the add-ons Truncator and AutoGrind Digital. These products represent a step forward towards more efficient and precise TIG welding, featuring environmentally friendly and cost-effective solutions.

Ultima-TIG®: Cost-effective Grinding

Ultima-TIG® is our environmentally friendlier wet grinder for tungsten electrodes used in TIG welding, minimizing wastage of the costly electrodes. Our unique construction includes a container that automatically collects dust particles, ensuring they do not end up in the environment. We take pride in our sustainability efforts, making it easier for users to send the tungsten dust for recycling. The returned grinding dust is cleaned and reused for applications like tools, electronic components, or aircraft parts, thereby saving the environment from CO2 emissions for every kilogram of recycled tungsten dust. This groundbreaking approach reflects our commitment to minimizing our environmental impact and promoting a more sustainable future.

Truncator: Enhanced Electrode Tip Truncation

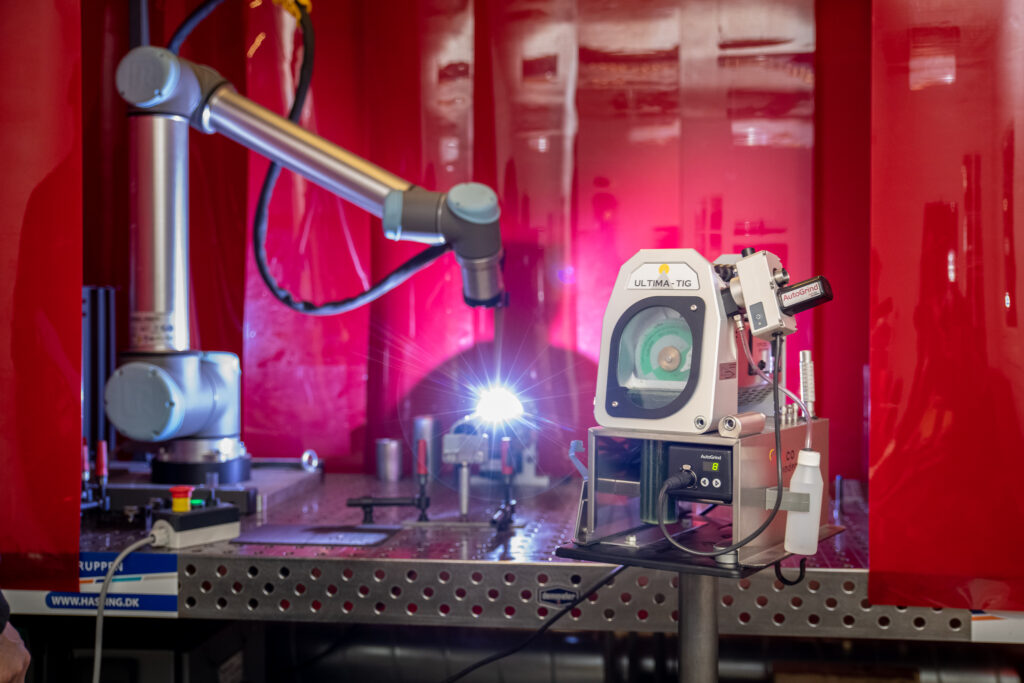

We have also introduced an innovative solution called the Truncator. This separate module is designed for truncating the tip of the ground tungsten electrode used in TIG welding. The Truncator module can be easily attached to our Ultima-TIG® and Ultima-TIG®-Cut grinders. It can even work in conjunction with AutoGrind Digital on the Ultima-TIG®.

AutoGrind Digital: Precise, Simple, and Swift Electrode Grinding

We are also introducing AutoGrind Digital, an automated grinding process that ensures precise and uniform electrode grinding. It is also the best ergonomic solution for the user, because the electrode holder’s automatic rotation means no more repeated movements in the wrist and arm. It ensures a quick replacement of the electrode in the welding torch, because there is no need to adjust each electrode separately. AutoGrind Digital is designed to be mounted on our Ultima-TIG® and Ultima-TIG®-Cut grinders and can handle electrodes up to Ø4 mm.

More blog posts

EuroBLECH

EuroBLECH

EuroBLECH 2026 in Hannover with Bymat Learn more

WeldEnd

WeldEnd

WeldEnd 2026 in Zella-Mehlis, Germany Learn moreContact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.

Get in touch

Book a free demo

Our Tungsten grinders reduce the use of Tungsten electrodes by up to 50%. Are you interested in evaluating how much you can save and how our grinders can meet your welding needs? Please enter your information below and we will ensure that the nearest distributor will contact you to find the best solution that suits you.

Get in touch with a distributor

Please fill out the form – and we will connect you with a distributor in the USA.