Large French service and installation specialist is equipped with our grinders

The company employs 4000 people worldwide and has 75 welding stations while most of the welding activities are manual. The reason behind their purchase is their desire to protect the welders from harmful grinding particles and from injuries associated with open belt or bench grinding.

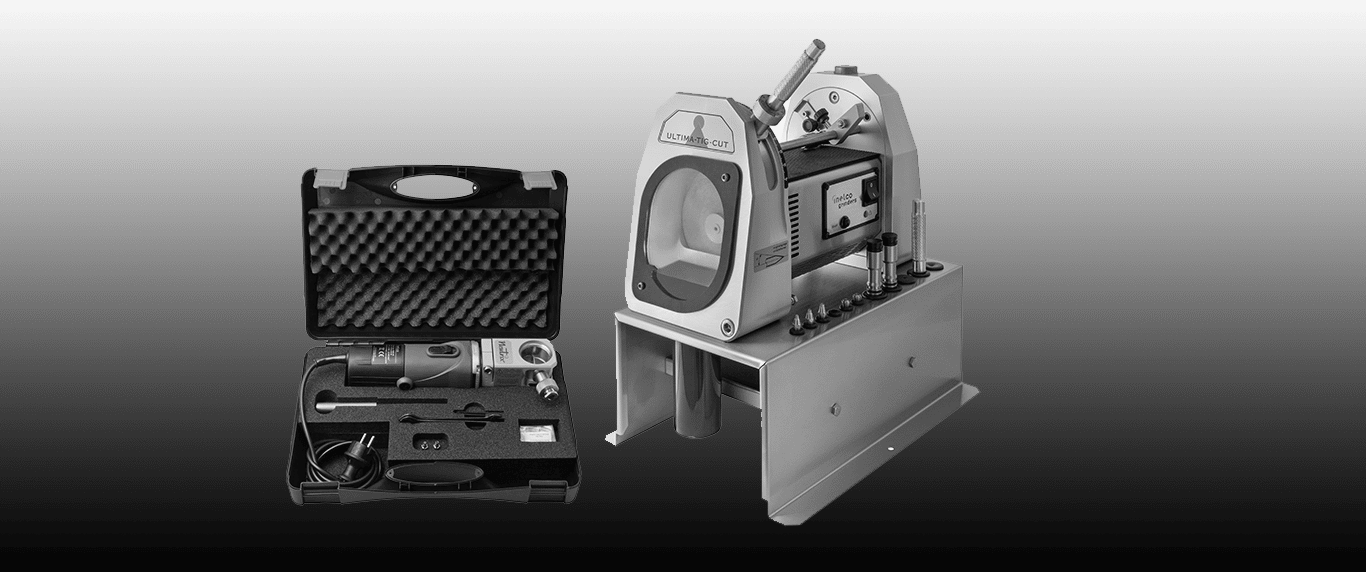

They have effectively implemented 18 Ultima-TIG®-Cuts, which is our stationary wet grinder, and can be found in their workshops. Furthermore, they have purchased 12 Neutrix machines, our portable grinder, and use them for the construction sites.

Advantages

It is important for them that they experience great benefits from using our grinders as they guarantee the following:

- Protects the welder by ensuring a more secure way of grinding and cutting of the electrodes

- Higher quality grinding and cutting due to the perfect centring of the tip, precise angle adjustment and safe cutting without the risk of breaking the electrode.

- Economic gain as one can avoid a lot of Tungsten electrode waste when using our grinders because it grinds down to 8 mm. This translates to considerable savings. In fact, they see a return on their investment in just 18 months.

- Environmentally friendly due to the sealed grinder, collection of grinding dust as well as minimal electrode waste.

Their welders enjoy using our grinders because they match their needs by the flexibility of fixing it onto a worktable, it does not take up space, the grinders are user-friendly, and they ensure precise grinding of each electrode in the desired angle. Most importantly the welder’s safety is in focus. When grinding the risks of exposure are the highest both due to the risk of inhaling the harmful particles from the grinding dust but also because of the risk of cuts, vibrations or even perforation.

Take a look at our Neutrix or our Ultima-TIG®-Cut to learn more about the benefits of using our grinders!