Service for AutoGrind Digital

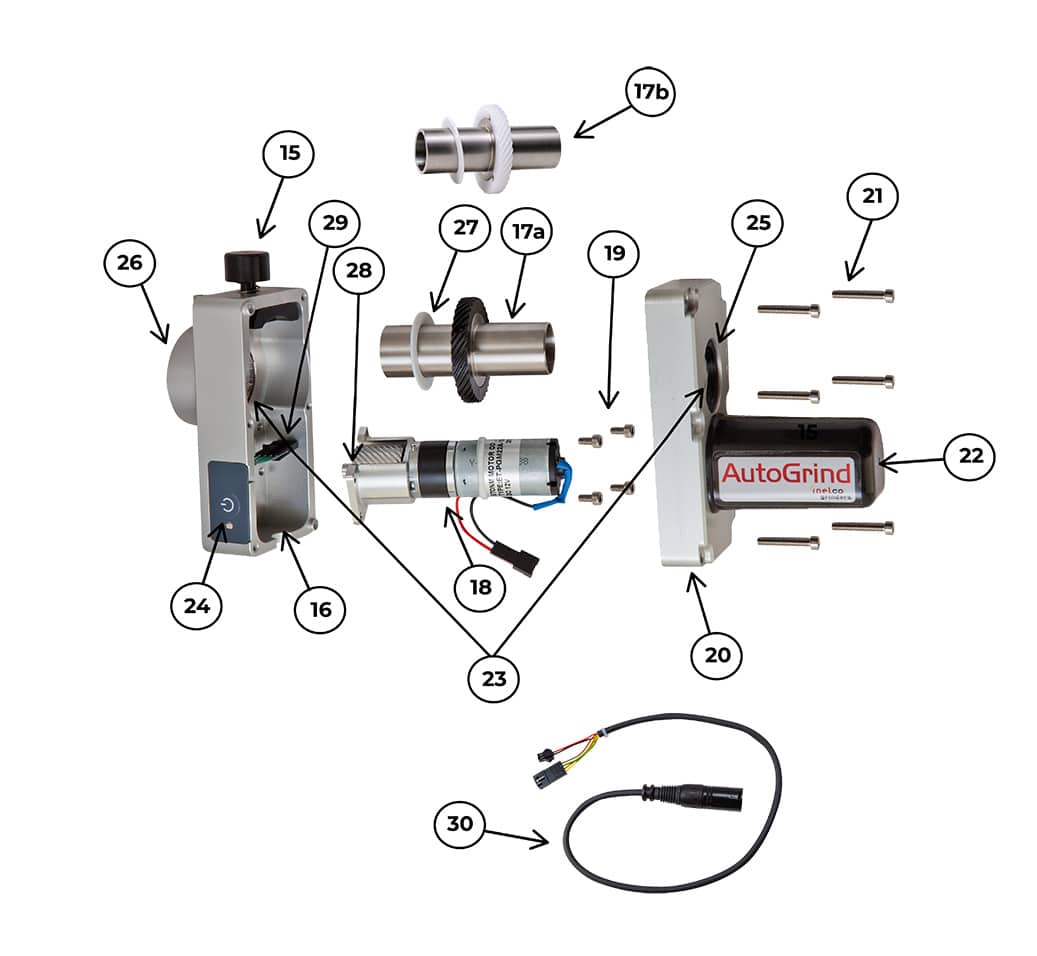

Spare parts overview

| Pos. | Item no. | Description |

|---|---|---|

| 1a | 75550005 | Grinding module for Auto-Grind V2 |

| 1b | 75560005 | Grinding module for AutoGrind Digital V3 |

| 2 | 75550006 | Control box |

| 3 | 74250014 | Mains cable 3×1,0 |

| 4 | 74300014 | Grinding cable male C14-Schuko female |

| 5a | 75550020 | Electrode holder for AutoGrind Digital |

| 5b | 75560020 | Electrode holder for AutoGrind Digital V3 |

| 6 | 44470213 | O-ring Ø13×1.5 mm |

| 7 | 44550022 | Stretching screw for mounting on Ultima-TIG/-Cut |

| 8 | 44550018 | Drain ring |

| 9 | 44492510 | Pipe fitting |

| 10 | 75550019 | Tightening screw with drain incl. packing ring |

| 11 | 75550030 | Drain bottle set |

| 12 | 44491215 | Bottle holder |

| 13 | 40310620 | M6x14 hexagon screw |

| 14 | 44510435 | Hexagon key 3 mm |

| 15 | 75550013 | Blocking module for AutoGrind |

| 16 | 44550000 | House AutoGrind |

| 17a | 75550012 | Axle module AutoGrind |

| 17b | 75560012 | Axle module AutoGrind V3 |

| 18 | 75550011 | Motor module for AutoGrind |

| 19 | 40310306 | Allen screw M3x6 |

| 20 | 44550001 | Top grinding module AutoGrind |

| 21 | 40310320 | Allen screw M3x20 |

| 22 | 44550002 | Motorcap |

| 23 | 44550020 | Bearing AutoGrind |

| 24 | 17110035 | On/off button AutoGrind |

| 25 | 44551300 | Packing box AutoGrind |

| 26 | 40110511 | Screw M4x12 |

| 27 | 44550017 | Teflon disc |

| 28 | 44550021 | Motor Bearing AutoGrind |

| 29 | 74491429 | Plug Foil Key female |

| 30 | 75550010 | Control cable |

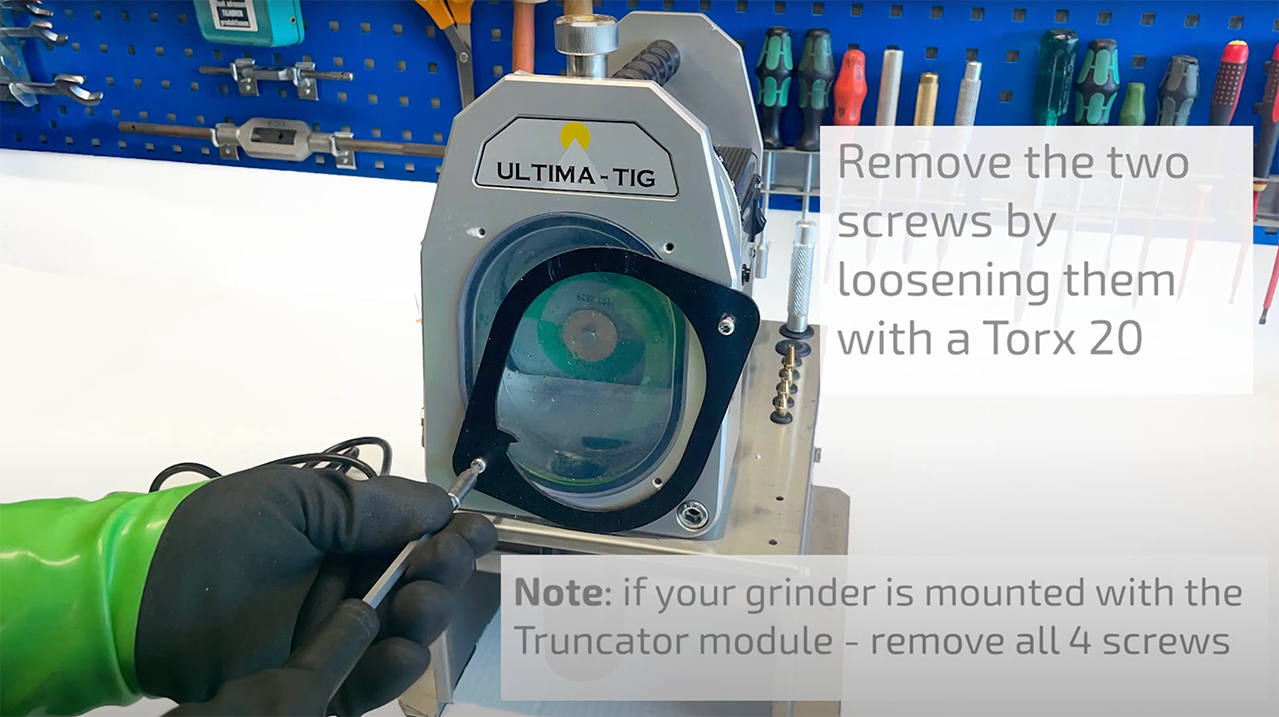

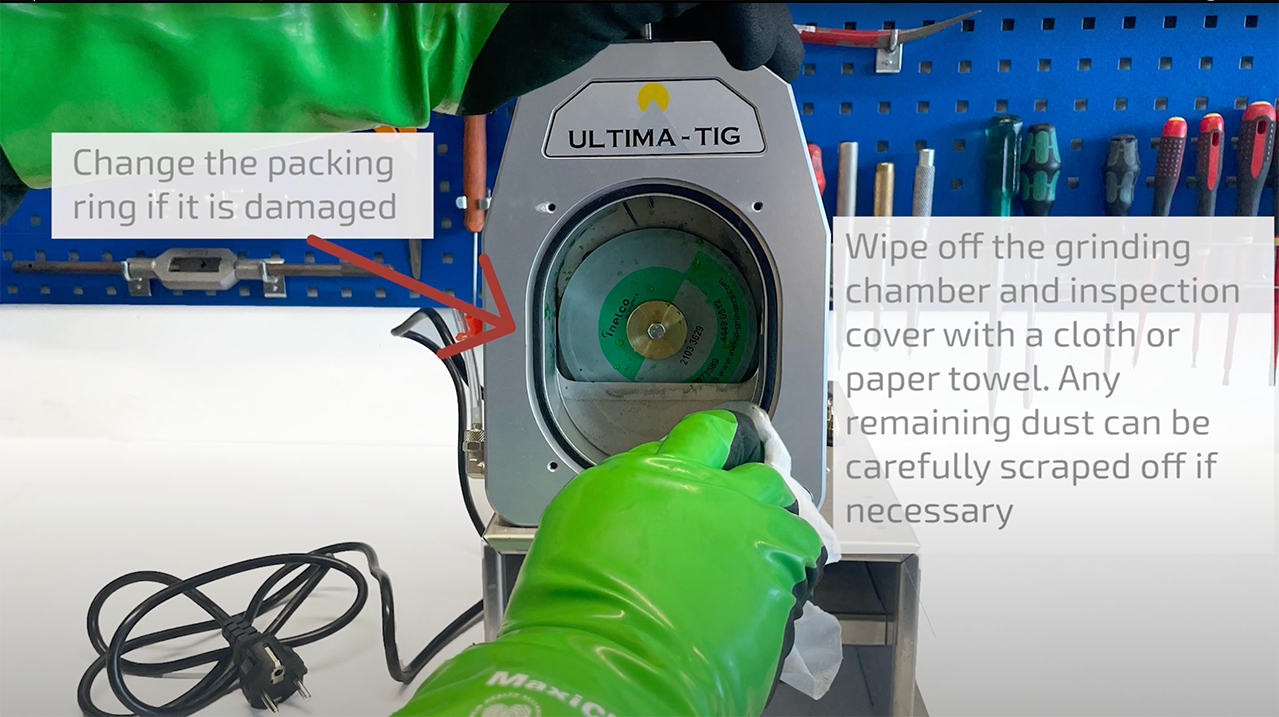

Scheduled maintenance

Important

The AutoGrind module and control box are maintenance free but needs to be kept dry and clean.

The rotating part in the AutoGrind module is running in two bearings. If dirt and moisture is getting into the bearings, they will not last so long, and it will affect the grinding result.

Changing the two bearings

When the two bearings are worn out, they need to be changed, please contact the distributor where you purchased the AutoGrind or contact us.

Videos

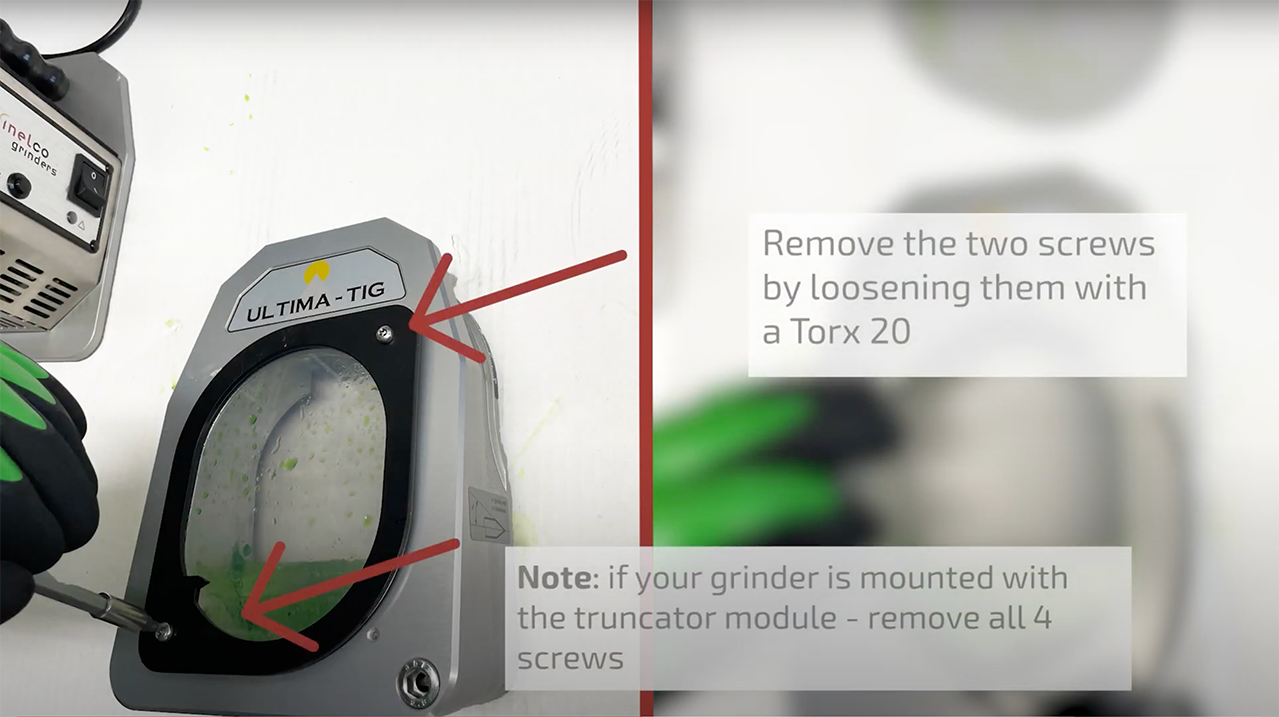

Please take a look at the service videos for the Ultima-TIG line. Let us know if you wish to see other service videos.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.