Service for Truncator

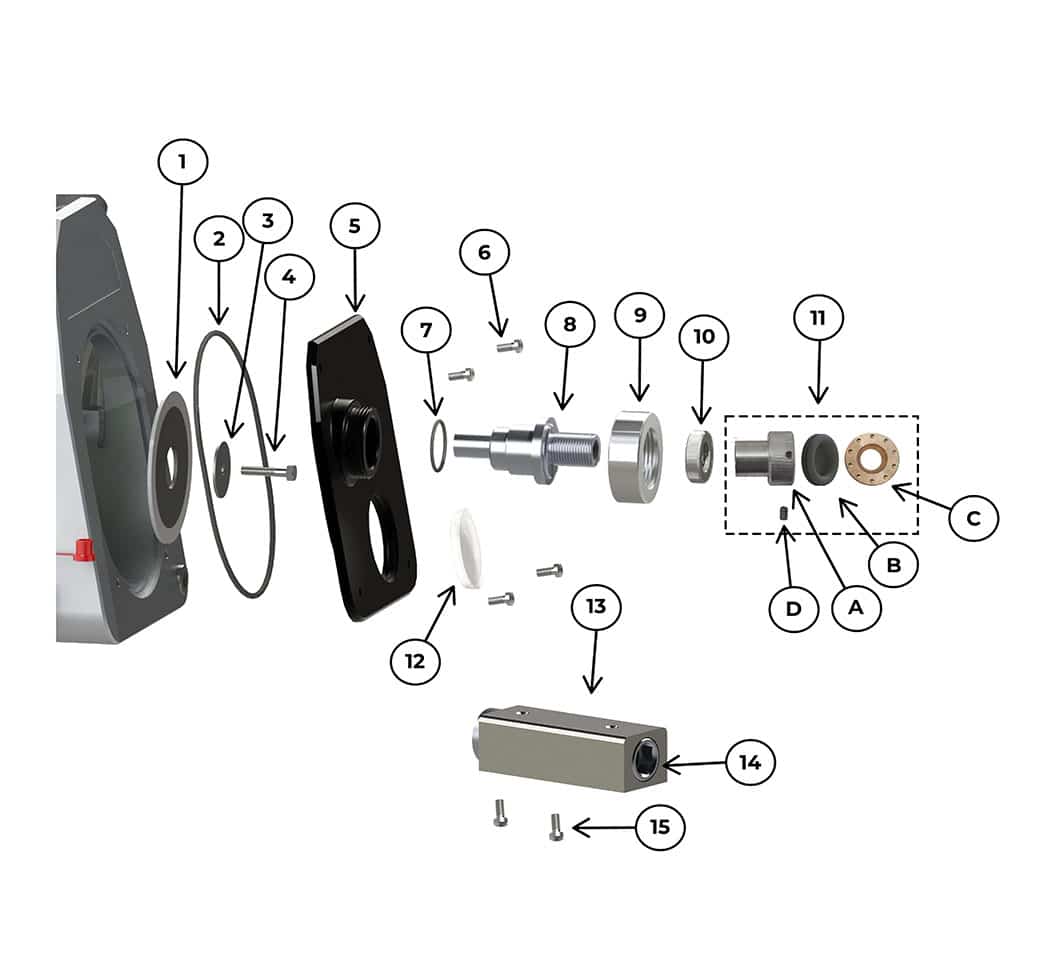

Spare parts overview

| Pos. | Item no. | Description |

|---|---|---|

| 1 | 44490517 | Diamond Disc Truncator |

| 2 | 44520009 | Packing ring for insp.cover |

| 3 | 41530540 | Washer Ø5×30 |

| 4 | 44496525 | Screw M5 Lefthand Stainless |

| 5 | 44490910 | Frame Truncator |

| 6 | 40320410 | Retaining screw M4x10 |

| 7 | 44470224 | O-ring Ø24×2 mm |

| 8 | 44523010 | Eccentric guide /44523011 Eccentric guide - S |

| 9 | 44523005 | Eccentric guide lock |

| 10 | 44520048 | Locknut |

| 11a | 44520004 | Tightening screw |

| 11b | 44470124 | Rubber pack (membrane), Ø25 mm |

| 11c | 44520027 | Bronze bearing Outward / 44521027 - S |

| 11d | 40310404 | Pointed screw M4x6 |

| 12 | 44510290 | Inspection cover NX |

| 13 | 44523015 | House for stickout |

| 14 | 44523020 | Bolt for stick-out / 44523021 Bolt for stick-out -S |

| 15 | 40110406 | Screw M4x6 |

Scheduled maintenance

Inspection

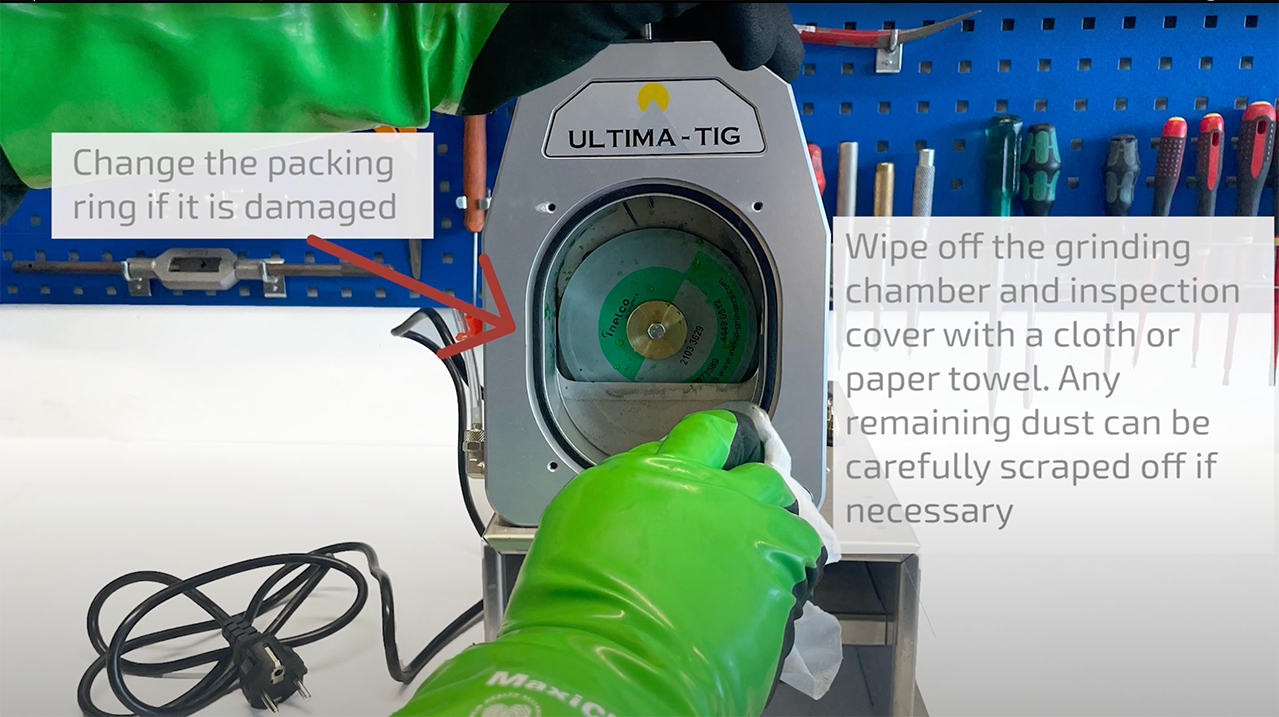

The Truncator module should typically be cleaned quarterly or after 5,000 grinding operations, in addition to when service is carried out on the Ultima-TIG® grinder or when the grinding disc for truncating needs to be replaced.

Cleaning is carried out by dismantling the Truncator module. Clean it in hot water and drying it with a dry cloth or paper.

We recommend that the packing ring, part no. 44520009 and 44470224, be replaced if this is damaged.

Videos

Please take a look at the various service videos for the different grinders. Let us know if you wish to see other service videos.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.