The Australian K-TIG

- A welding fairytale

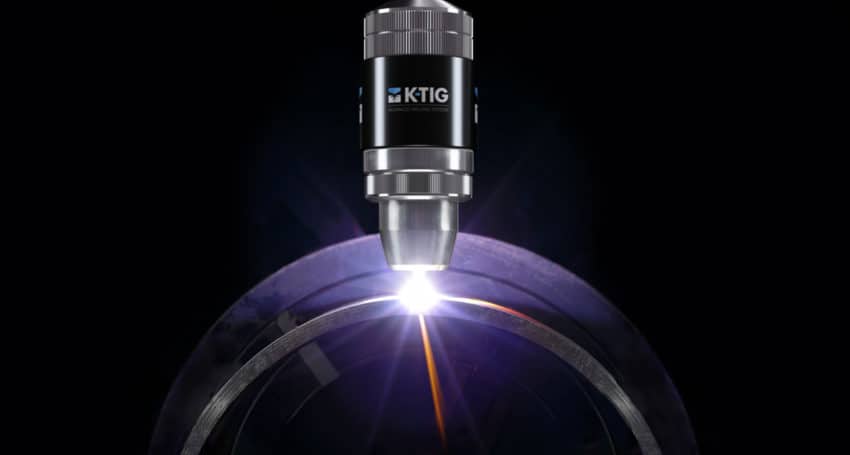

K-TIG is the developer and manufacturer of a patented, high productivity welding technology known as Keyhole TIG.

K-TIG technology reduces multi-hour conventional TIG welds to just 3 minutes – especially welding of large diameter and thick plate pipes and fittings.

K-TIG is a precision welding process which benefits greatly from an electrode which is ground to exact requirements.

“For our purposes, we have found

-Neil Le Quesne, President Market Development, K-TIG

the ideal grinder – an Inelco

Ultima-TIG.

We’ve shipped these grinders

alongside our systems for years

to customers in 20 countries, and

they have performed flawlessly.”

What we value most is accuracy, consistency, repeatability and ease of use for our customers. When we find something as well engineered and reliable as this, we stick with it – and we have, says Neil Le Quesne.

We are thrilled about this collaboration with K-TIG and hope to provide more precision grinders to improve the conditions for your weld! Check out our Ultima-TIG.