Automated welding demands consistent grinding of electrodes

A German luxury car brand, who welds their exhaust systems in stainless steel, utilize an automated welding process and therefore requires the quality of the grinding to be top of the class. The quality refers to a consistent grinding angle every time as well as having a fast grinding process, which the automated grinding process can offer.

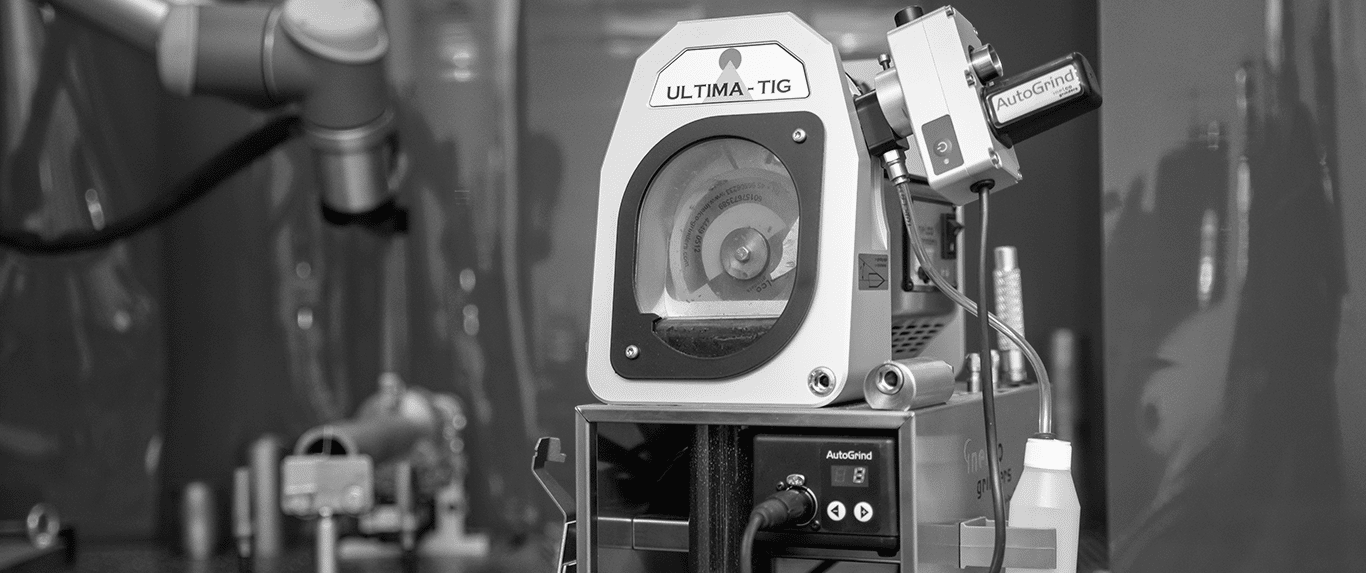

Their pre-ground electrodes only had a service life of 30%, now using Ultima-TIG®-Cut with our AutoGrind add-on, their electrodes reach a 100% service life, resulting in great savings and greater efficiency.

This client became a part of the development of the AutoGrind by providing input in the process and testing the prototypes. Hence, we launched the add-on AutoGrind in 2015.

Our AutoGrind Digital can grind up to 10 electrodes in 5 minutes and not only delivers a shorter grinding time but a better ergonomic solution for the user when grinding many electrodes as well.

Read more about our add-on AutoGrind Digital here.