Service for Ultima-TIG-S

Spare parts overview

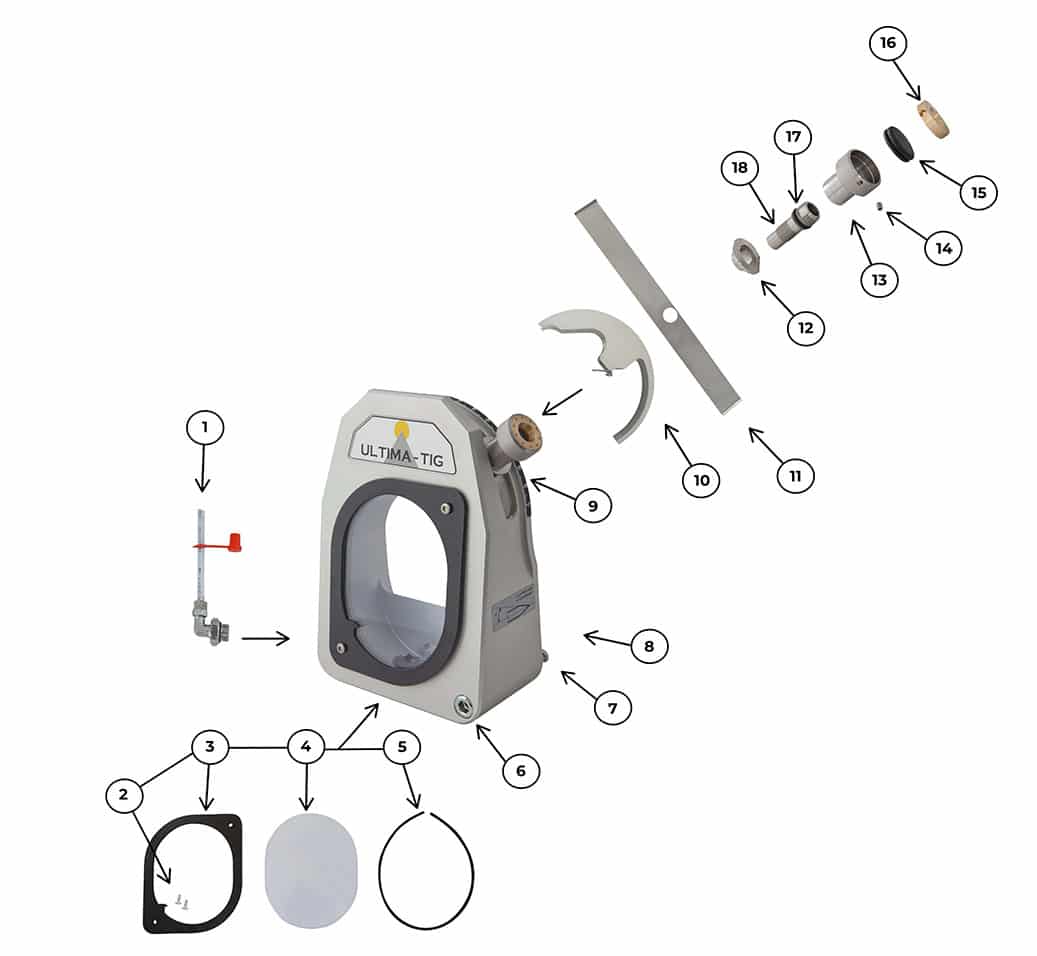

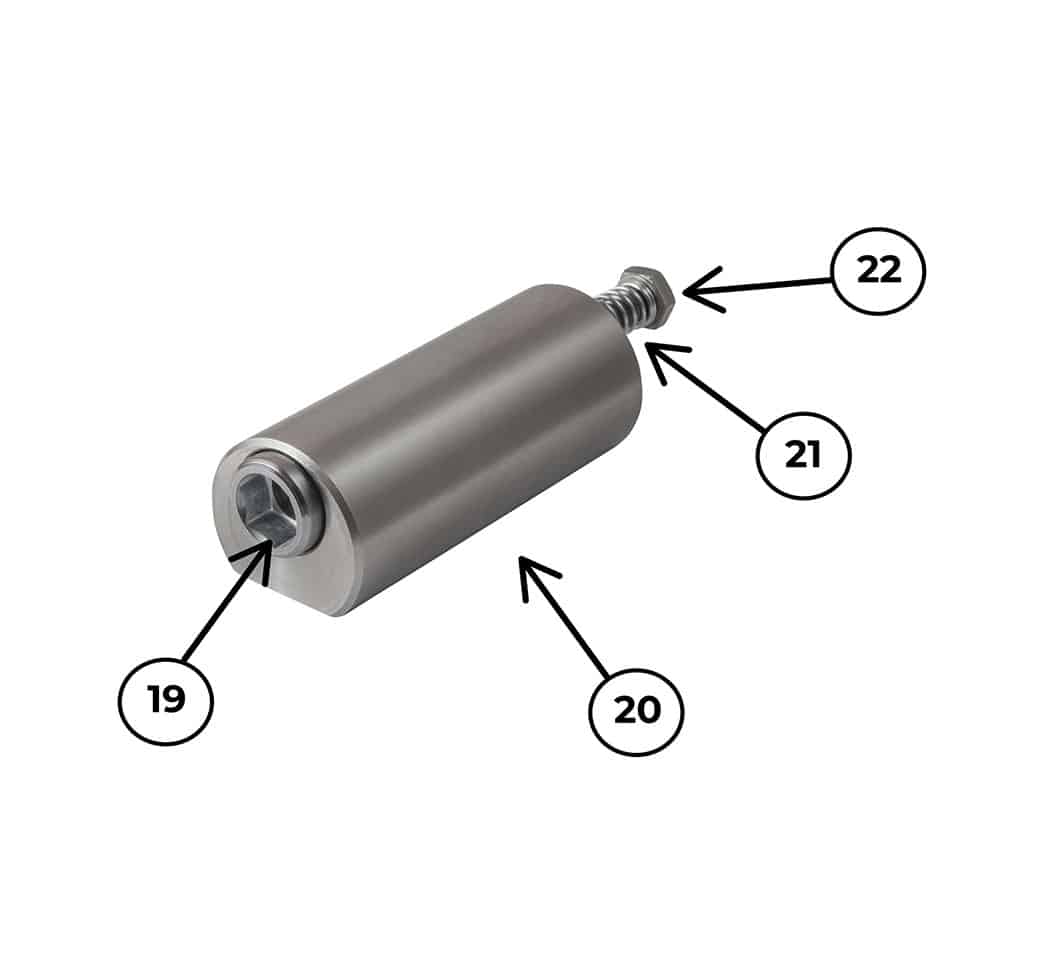

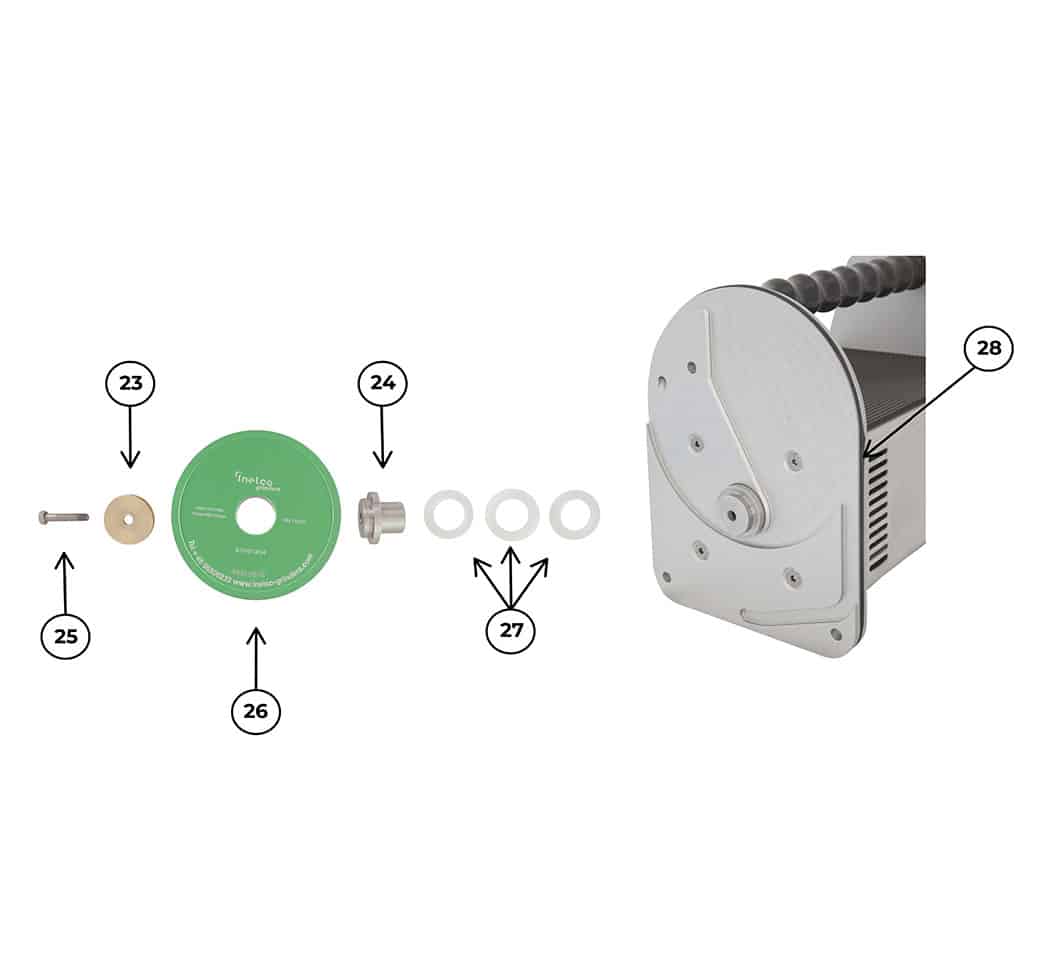

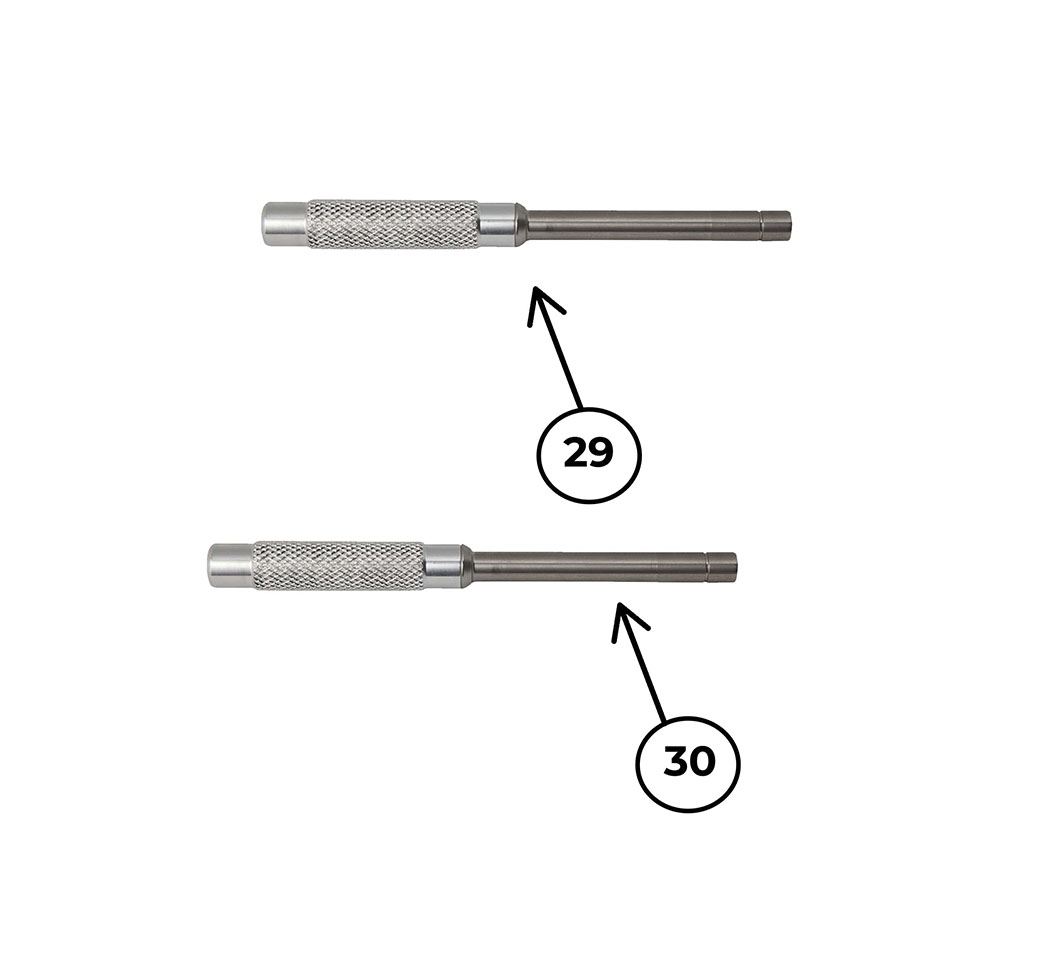

| Pos. | Item no. | Description |

|---|---|---|

| 1 | 75522500 | Drain/filling pipe |

| 2 | 40320410 | Retaining screw M4x10 |

| 3 | 44490901 | Frame Black W95/1-92 |

| 4 | 44490700 | Plastic Inspection Cover W95/1-07 |

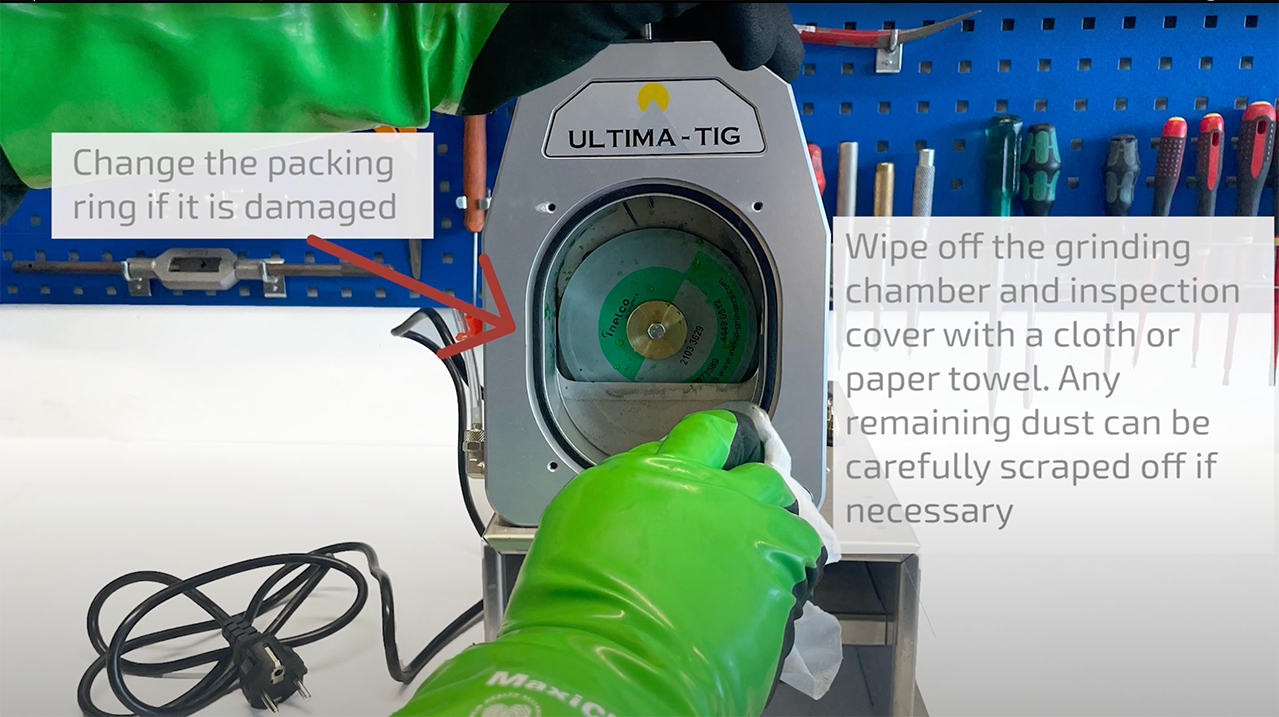

| 5 | 44520009 | Packing ring for insp.cover |

| 6 | 44520024 | Screw for stick-out |

| 7 | 44520028 | Spring f. stick-out |

| 8 | 40040670 | Screw M6x70 |

| 9 | 62189220 | Degree scale |

| 10 | 75521001 | Angle adjustment 4,8 |

| 11 | 44520007 | Metal strip stainless |

| 12 | 44520008 | Degree scale bush |

| 13 | 44521004 | Tightning screw 4,8 mm UT-S |

| 14 | 40310404 | Pointed screw M4x6 |

| 15 | 44470124 | Rubber pack (membrane), Ø25 mm |

| 16 | 44520027 | Bronze bearing Outward |

| 17 | 44470312 | O-ring Ø12×2.5 mm |

| 18 | 44521022 | Stretching screw 4,8 |

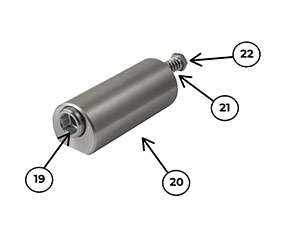

| 19 | 44520025 | Bolt for Stickout 4,8 mm UT-S |

| 20 | 44521030 | House for stickout 4,8 mm UT-S |

| 21 | 44520028 | Spring f. stick-out |

| 22 | 40040670 | Screw M6x70 |

| 23 | 41530530 | U-wheel UT |

| 24 | 44520017 | Bush for wheel |

| 25 | 44496525 | Screw M5 Lefthand Stainless |

| 26 | 44490512 | Diamond Disc Ultima-TIG |

| 27 | 44520018 | Weather ring for bush |

| 28 | 44520010 | Packing ring for rear plate |

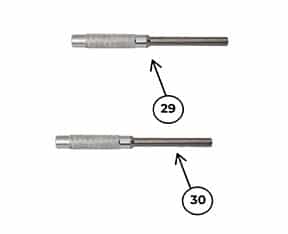

| 29 | 75521023 | Electrode holder for Ø4,8-8mm UT-S |

| 30 | 75520123 | Electrode holder for UT-S Ø0,8-4,0 mm |

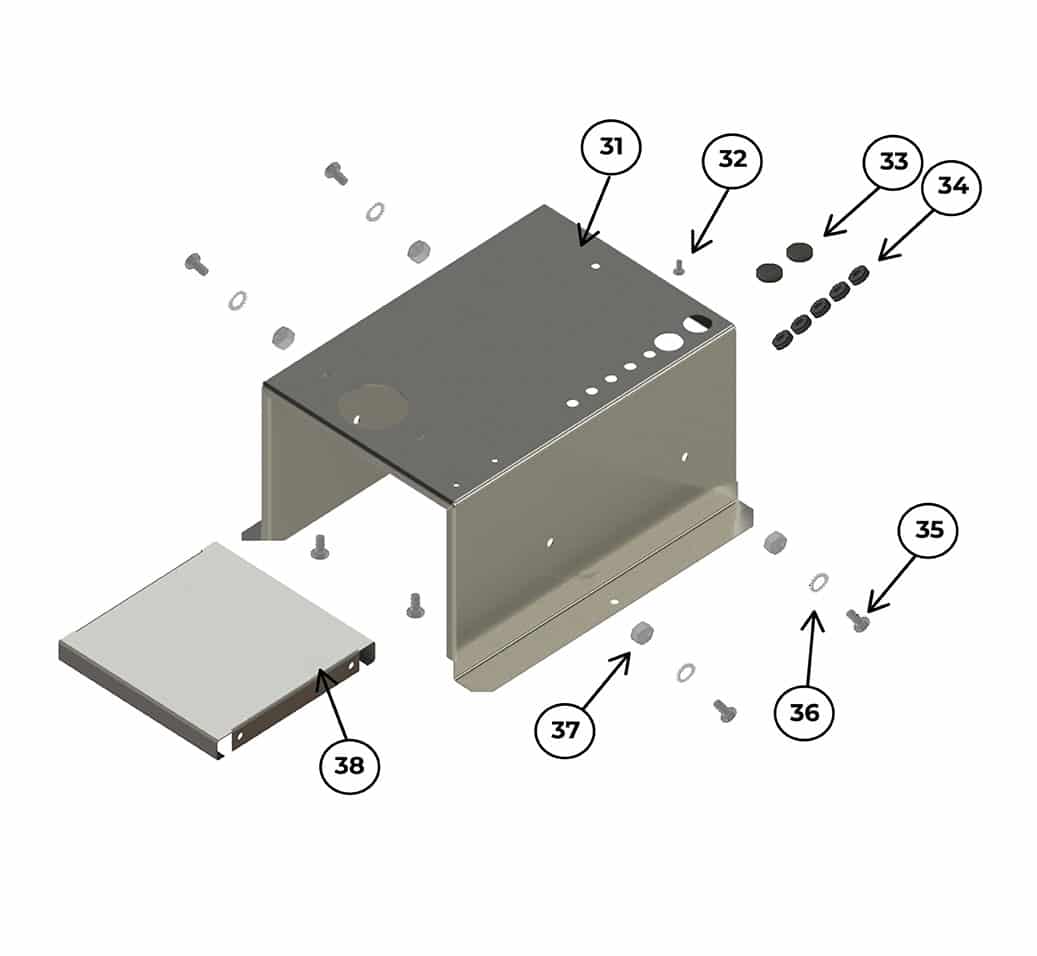

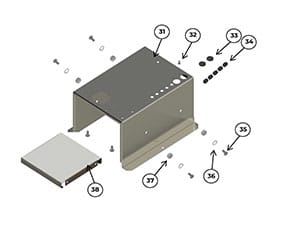

| 31 | 44529011 | Work table UT/UT-S |

| 32 | 40110406 | Screw M4x6 |

| 33 | 44470124 | Rubber pack (membrane), Ø25 mm |

| 34 | 44470029 | Rubber lead-in ring ø9 mm |

| 35 | 40040610 | Bolt stainless M6x10 |

| 36 | 41711106 | Tooth lock washer ø6 |

| 37 | 41110605 | Nut M6 |

| 38 | 44529002 | Stiffening plate UT+CUT |

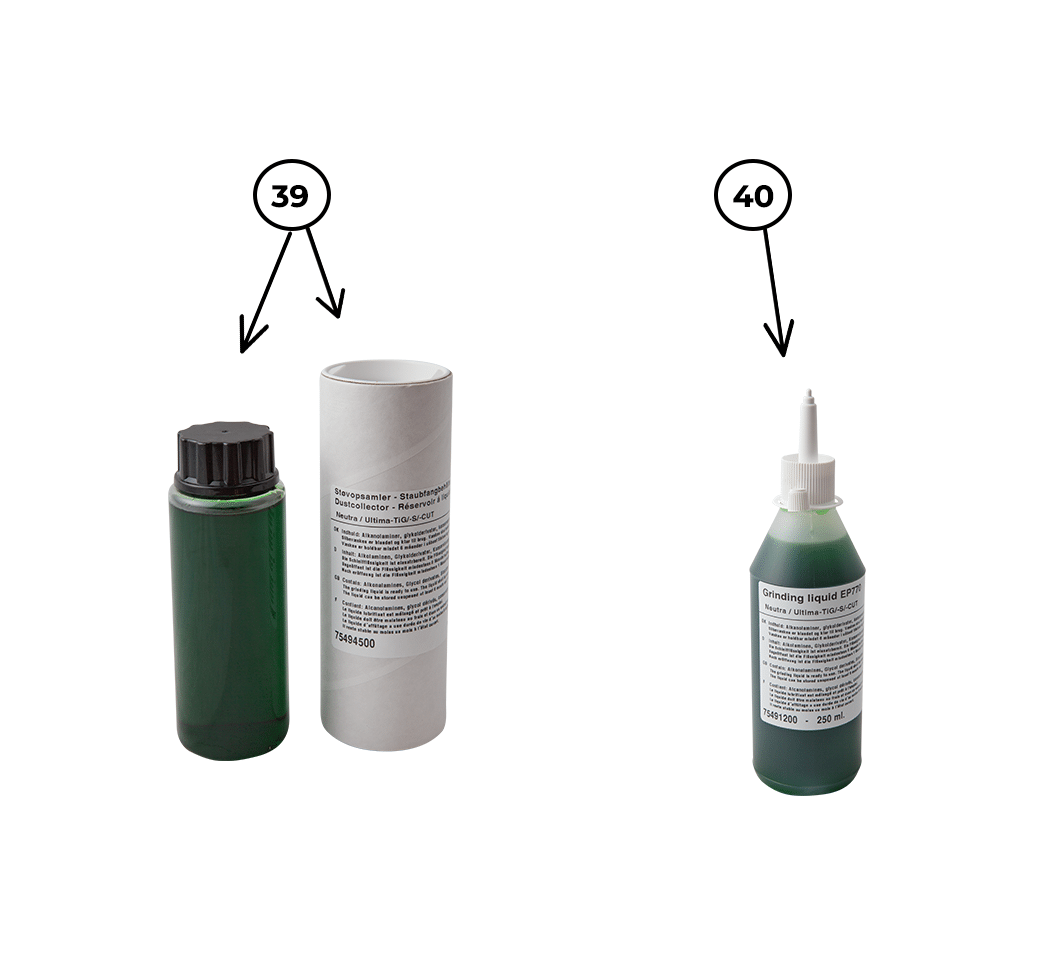

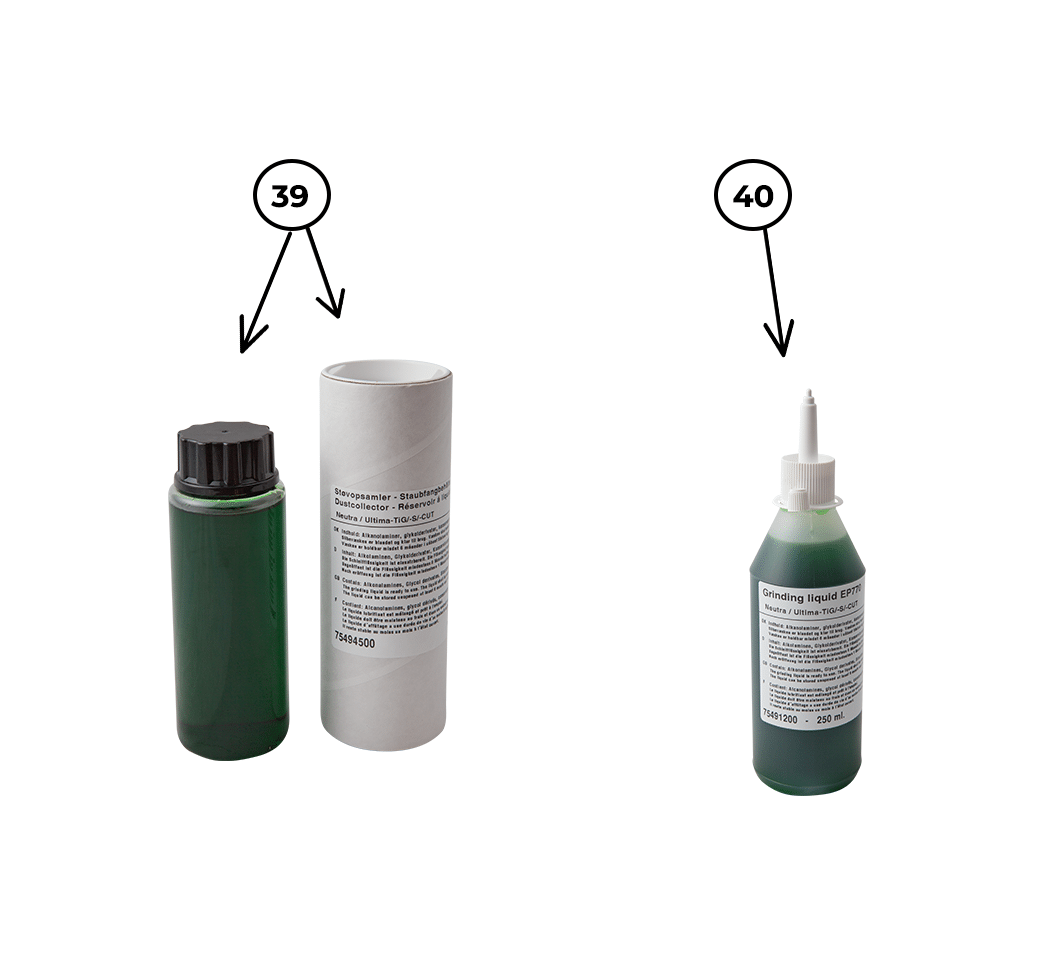

| 39 | 75494500 | Dust Collector incl. liquid (UT + W95/1-45) |

| 40 | 75491200 | Grinding liquid 250 ml W95/1-12 |

Scheduled maintenance

Daily inspection

Visual inspection for damage, leaks, fluid level and degree of contamination of the grinding fluid and the grinding console.

Ensure free movement of the angle adjustment.

Monthly inspection/

1000 grind service

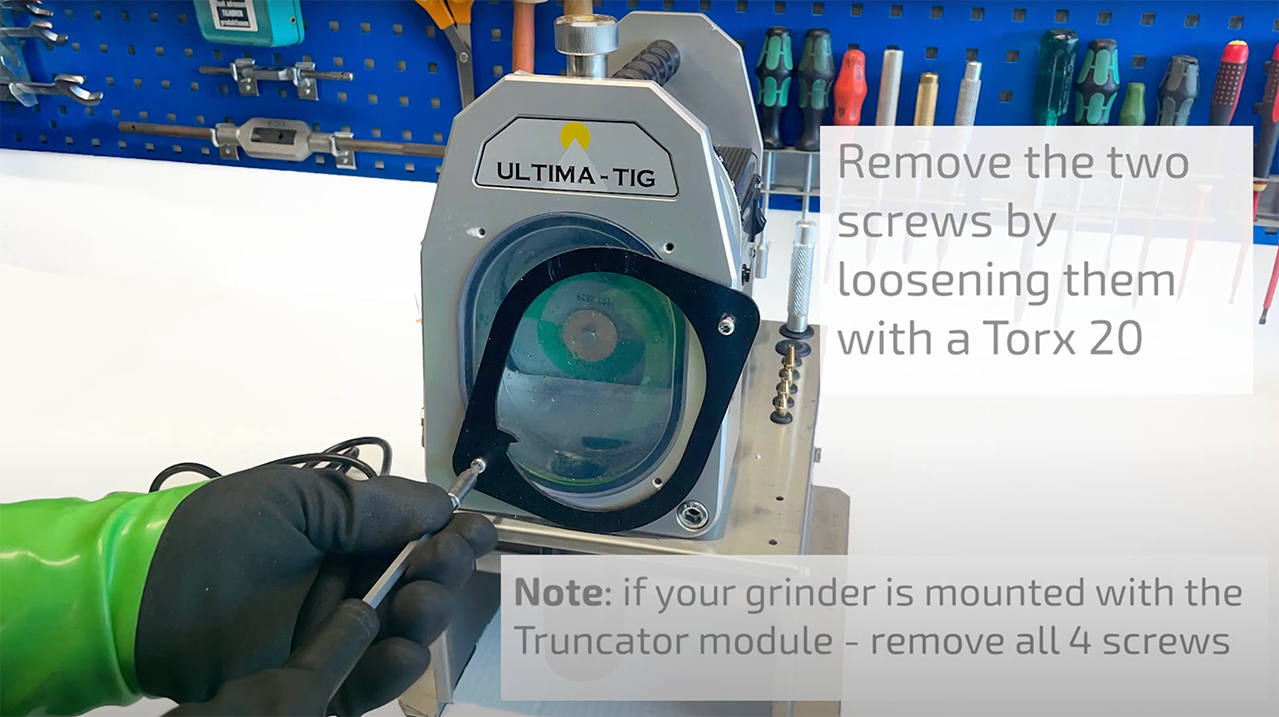

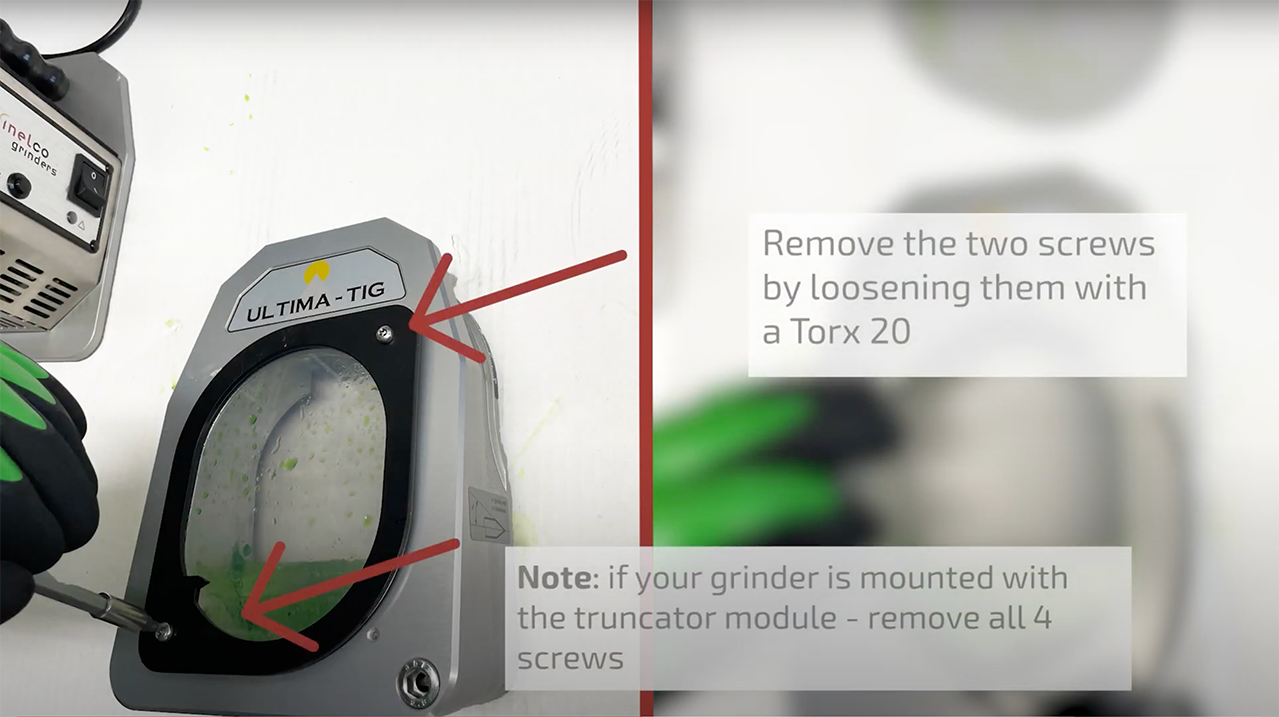

Clean the inside of the grinding chamber when the LED lights yellow or at least once every month following the steps described in the manual or see the video.

Quarterly inspection/

5000 grind service

Visual inspection for damage, leaks, fluid level and degree of contamination of the grinding fluid and the grinding console.

Videos

Please take a look at the various service videos for the different grinders. Let us know if you wish to see other service videos.

Contact us

Do you have any questions about our products or another subject? Then feel free to reach out to us using the contact form, email or call us directly. We look forward to hearing from you.